Filter cloth

-

PE500c1 Filter Cloth Product Introduction

1. Product Overview The PE500c1 filter cloth is a premium filtration material meticulously crafted to deliver outstanding performance in a wide array of filtration applications. Made from high-quality polyethylene (PE) with the unique characteristics of the “c1″ variant, it offers a combination of durability, efficiency, and reliability that sets it apart in the market.

2. Material Properties – **High-Quality Polyethylene Base**: The PE500c1 filter cloth is constructed from top-grade polyethylene, which provides it with excellent physical properties. This material has a high tensile strength, allowing the filter cloth to withstand the rigors of the filtration process without tearing or deforming easily. It can endure significant mechanical stress, whether it’s during the filtration operation or when handling the cloth for installation and cleaning. – **Unique “c1″ Characteristics**: The “c1″ designation indicates specific enhancements or modifications to the base PE material. These may include optimized molecular structure for improved chemical resistance, better fiber orientation for enhanced filtration efficiency, or surface treatments that contribute to its anti-clogging and easy-release properties. These unique features make the PE500c1 filter cloth more adaptable to various challenging filtration environments.

3. Key Features – **Superior Filtration Efficiency**: The PE500c1 filter cloth is designed with a precisely engineered pore structure. This allows it to effectively capture particles of different sizes, ensuring high-precision filtration. Whether it’s separating fine solids from liquids in chemical processes or removing contaminants from industrial wastewater, it can achieve excellent separation results, delivering a clear filtrate. – **Exceptional Chemical Resistance**: Thanks to its PE base and the “c1″ modifications, the filter cloth has strong resistance to a wide range of chemicals. It can withstand exposure to acids, alkalis, and many organic solvents without being damaged or deteriorating in performance. This makes it suitable for use in industries such as chemical manufacturing, where harsh chemical environments are common. – **Long Service Life**: Its robust construction and high-quality materials contribute to a long lifespan. The filter cloth can maintain its filtration performance over an extended period, reducing the need for frequent replacements. This not only saves on costs but also minimizes downtime associated with filter cloth changes, improving overall production efficiency. – **Good Cake Release and Anti-Clogging**: The surface properties of the PE500c1 filter cloth enable easy release of the filtered cake. Particles do not adhere firmly to the cloth, making it simple to remove the solids after filtration. Additionally, its design helps prevent clogging of the pores, ensuring continuous and unobstructed filtration even when dealing with viscous or sticky substances.

4. Application Areas – **Chemical Industry**: Widely used in chemical reactors for separating reaction products from solvents, purifying chemical intermediates, and filtering out impurities in chemical solutions. It can handle a variety of chemical processes with different requirements, providing reliable filtration performance. – **Mining and Mineral Processing**: In the mining industry, the PE500c1 filter cloth is employed for dewatering of mineral slurries, separating valuable minerals from waste materials, and treating mining wastewater. Its ability to withstand heavy loads and harsh environmental conditions makes it a preferred choice for these applications. – **Food and Beverage Production**: For filtering fruit juices, wines, edible oils, and other food products, the PE500c1 filter cloth meets strict hygiene standards. It ensures that the final products are free from contaminants while maintaining their taste and quality. – **Water Treatment**: In both industrial and municipal water treatment plants, it can be used for removing suspended solids, turbidity, and other impurities from water sources. It helps in producing clean water that meets the required quality standards for various applications.

5. Technical Specifications – **Filtration Precision**: [Specify the range of particle sizes it can effectively filter, e.g., 0.5 - 50 microns] – **Tensile Strength**: Longitudinal: [Provide the value in appropriate units, e.g., N/cm] Transverse: [Provide the value in appropriate units, e.g., N/cm] – **Operating Temperature Range**: [Specify the minimum and maximum temperatures, e.g., -10°C to 80°C] – **pH Resistance Range**: [Indicate the pH values it can withstand, e.g., 2 - 12]

If you have any questions or need more detailed information about the PE500c1 filter cloth, or if you have specific requirements for your filtration applications, please feel free to contact our professional team. We are committed to providing you with the best solutions and excellent after-sales support.

-

PE500/PTFE Filter Cloth Product Introduction

PE500/PTFE Filter Cloth Product Introduction

1. Product Overview The PE500/PTFE filter cloth combines the excellent properties of polyethylene (PE500) and polytetrafluoroethylene (PTFE), presenting itself as a high – performance filter material. It is engineered to meet the diverse filtration needs across multiple industries, providing efficient solid – liquid separation and ensuring long – term stable operation.

2. Material Characteristics -

**PE500**: This material endows the filter cloth with high tensile strength and good toughness, enabling it to withstand significant mechanical stress during the filtration process without easily deforming or breaking. It also exhibits good chemical resistance to a wide range of common chemicals, protecting the filter cloth from corrosion and extending its service life. –

PTFE: Known as “King of Plastics”, PTFE has outstanding chemical inertness, being resistant to almost all chemicals, including strong acids, alkalis, and organic solvents. Additionally, it has extremely low surface energy, resulting in excellent anti – sticking properties. Particles and residues are less likely to adhere to the surface of the PTFE – based filter cloth, facilitating easy cake release and reducing the frequency of cleaning.

3. Key Features – **High Filtration Efficiency**: With precisely controlled pore sizes, the PE500/PTFE filter cloth can effectively capture fine particles, achieving high – precision filtration. Whether filtering suspended solids in liquid or separating dust in gas, it can ensure the filtrate or discharged gas meets strict quality standards.

Long Service Life: Thanks to the excellent chemical and mechanical properties of its materials, the filter cloth has remarkable durability. It can maintain stable filtration performance over extended periods of continuous operation, reducing the frequency of replacement and thereby lowering overall operating costs.

**Good Chemical Stability**:

Resistant to various harsh chemical environments, it can be safely used in industries such as chemical engineering, pharmaceuticals, and electroplating, where highly corrosive substances are often present. – **Easy to Clean**: The anti – sticking property of PTFE makes cleaning a breeze. Both mechanical cleaning methods, such as backwashing and vibration, and chemical cleaning can effectively remove residues on the filter cloth, restoring its filtration performance quickly. ## 4. Application Scenarios – **Chemical Industry**: Ideal for filtering chemical reaction products, separating catalysts, and purifying chemical solvents. It can handle highly corrosive chemical media while maintaining high – quality filtration. – **Pharmaceutical Industry**: Used in the production process to filter pharmaceutical intermediates and final products, ensuring product purity and compliance with strict pharmaceutical standards. Its non – shedding and high – cleanliness characteristics are crucial in pharmaceutical manufacturing.

**Food and Beverage Industry**:

Suitable for filtering fruit juices, beverages, and edible oils. It meets food – grade safety requirements, ensuring no harmful substances are introduced during the filtration process and maintaining the taste and quality of food products. – **Mining and Metallurgy**: Helps in separating valuable minerals from ores and purifying wastewater generated during the mining and metallurgical processes. Its high – strength structure can withstand the harsh conditions of the mining environment.

5. Technical Parameters – *

*Filtration Precision**: [Specify the precise range, e.g., 0.1 - 100 microns] – **Tensile Strength**: [Provide the data, e.g., longitudinal tensile strength ≥ [X] N/cm, transverse tensile strength ≥ [Y] N/cm] – **Working Temperature**: – [X] °C to [X] °C – **pH Resistance Range**: [Specify the applicable pH range, e.g., 1 - 14]

If you have any further questions or specific requirements regarding our PE500/PTFE filter cloth, please feel free to contact us. Our professional team is ready to offer you detailed solutions and excellent after – sales service.

-

Acrylic needle felt filter cloth

Parameters Parameters Representation Reference Information parameters Product Name Fiberglass Polyester needle felt 750g/m² Product Code FB-PE750-MIT Physical properties Weave method needle felt Thickness 2.5 Weight 750 g/m² Width 1.8m-2.2m Loss on Ignition (%) ≥10 Chemical Finish PTFE impregnation Air Permeability (L/m²S@200Pa) 30- 100 Tensile strength( N/5cm ) Warp 1300 Weft 1500 Tensile elongation(%) Warp 8 Weft 8 Temperatu... -

Anti-Static Needle Felt Cloth

Parameters Parameters Representation Reference Information parameters Product Name Anti-Static Needle Felt Cloth Product Code AASF-PE550 AS Cloth Physical properties Weave method needle felt Thickness 2.0±0.08 Weight 550 g/m² Width 1.8m-2.1m customizing Loss on Ignition (%) ≥10 Chemical Finish PTFE coating Optionally Air Permeability (L/m²S@200Pa) 30- 80 Tensile strength( N/5cm ) Warp ≥1200 Weft ≥1300 Tensile elongation(%) Warp ≤35 ... -

Fiberglass cloth

The fiberglass is an inorganic fiber whose main component is SiO2. It is obtained by melting the glass frit at a temperature of 1300-1600 ° C, drawing filaments from the molten state and rapidly quenching. There are two kinds of filter materials: C glass (medium-alkali glass or soda calcium silicate glass) and E glass (alkali-free glass or aluminoborosilicate glass). The most advantages of fiberglass is high temperature resistance, good dimensional stability, and high tensile breaking strength. In terms of chemical corrosion resistance, glass fiber is stable to other media except hydrofluoric acid and high temperature and strong alkali. The fiberglass filter bag is resistant to high temperature, abrasion, water and oil.

-

Nomex Cloth

Nomex/Aramid needle punched felt is one of the most common materials used to make filter bags. And it is not flammable nor ignition, suitable for high temperature environment. Nomex/Aramid Properties Material Working Instant Temperature Abrasion Resistance Hydrolysis Resistance Acid Resistance Alkali Resistance Oxidation Resistance Temperature Aramid Needle Felt 220℃ 240℃ Good Middle Middle Good Middle Product name Aramid needle felt 550g/m² with PTFE membrane Prod... -

P84 filter Cloth

P84 punched felt is a high temperature filtration media used in pulse jet baghouse dust collectors. This material performs well in dry, high heat applications. It is strong, abrasion resistant and good for applications up to 460° F.

-

PTFE Cloth

PTFE (Polytetrafluoroethylene) filter felt is a polymer material with excellent chemical resistance, high temperature resistance and low friction coefficient. It is used in many industrial applications requiring high temperature, corrosive gas or liquid filtration. It is one of the most common materials used to make filter bags. Advantages of PTFE Filter Felt ⚫ Chemical resistance: PTFE has excellent chemical resistance and can resist the erosion of a variety of corro... -

PE felt Cloth

Parameters Parameters Representation Reference Information parameters Product Name Polyester Needle Punched Felt Cloth Product Code AASF-PE550 Physical properties Weave method needle felt Thickness 1.8-2.2mm Weight range 100-550 g/m² Width 1.8m-2.2m Loss on Ignition (%) ≥10 Chemical Finish singe and calendeing and heat setting Air Permeability (L/m²S@200Pa) 30- 80 Tensile strength( N/5cm ) Warp ≥1200 Weft ≥1300 Te... -

FMS Cloth

Product Code

-

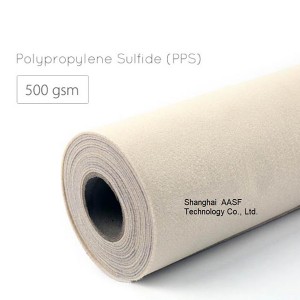

PPS filter cloth

PPS (Polyphenylene Sulfide) needle-punched filter felt is a filter material with excellent performance in high temperature and corrosive environments. PPS is a special synthetic polymer that can maintain stability under high temperature and chemical corrosion conditions, so it is often used in flue gas purification and high temperature gas filtration in industrial fields.

-

PP filter cloth

PP(Polypropylene) needle punched felt is one of the most common materials for filter cloth. Polypropylene filter needle felt is a specific type of needle felt commonly used in industrial filtration applications.