Glass Fiber Filter Bags: Technological Innovation Drives Industry Development

In this era of increasing environmental awareness, the control of dust pollution in industrial production processes has become a focus of attention for major enterprises. As an efficient dust removal device, glass fiber filter bags have unique performance advantages and occupy an important position in the field of industrial dust removal. With the continuous advancement of technology, the production technology of glass fiber filter bags is also constantly innovating, bringing new opportunities and challenges to its market development.

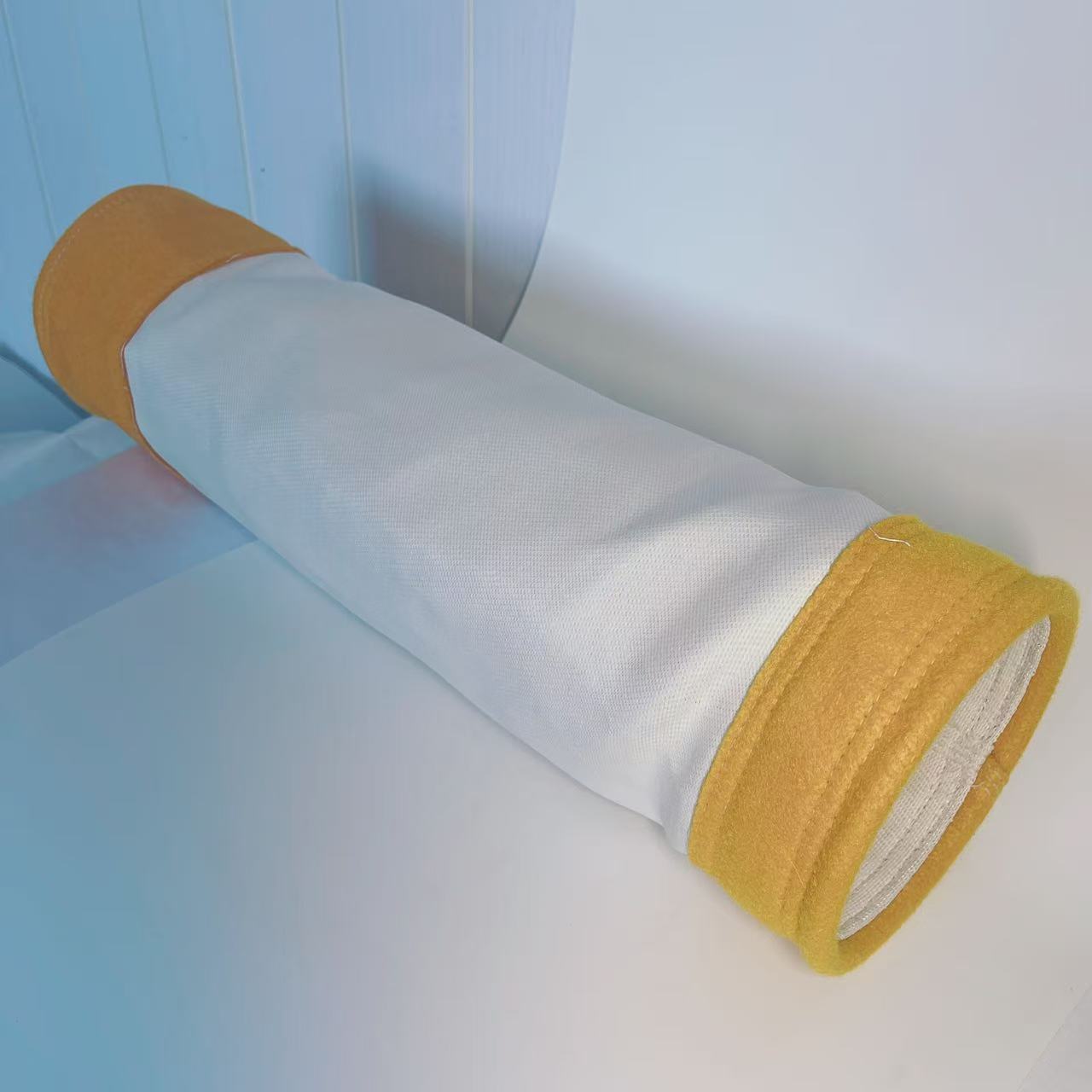

From a technical perspective, the production process of fiberglass filter bags has been continuously optimized. The traditional production of fiberglass filter bags mainly adopts the glass fiber needle-punched felt process. After cutting the glass fibers and conducting needle-punching to form the felt, a series of post-processing procedures are carried out to produce the filter bags. Although this process can meet basic filtration requirements, it still has certain limitations in terms of filtration accuracy, air permeability, and durability. In recent years, with the application of new materials and technologies, significant breakthroughs have been made in the production process of fiberglass filter bags. For example, using fiberglass expanded yarn as the raw material, a high-density thick-type fiberglass fabric is woven through a special weaving process. Compared with the traditional needle-punched felt, this fiberglass fabric has higher strength and better wear resistance, which can effectively extend the service life of the filter bags. At the same time, in terms of surface treatment technology, new progress has also been made. Through heat setting, pressure bonding, and treatment with waterproof agents such as PTFE (polytetrafluoroethylene) on the surface of the fiberglass fabric, a dense protective film is formed on the surface of the filter bag. This not only improves the waterproof and oil-resistant performance of the filter bag but also enhances its resistance to chemical corrosion, enabling it to better adapt to complex and variable industrial environments.

In addition to the improvement of production processes, the design of glass fiber filter bags has also been innovated. To enhance the filtration efficiency and reduce the operating resistance, some manufacturers have developed glass fiber filter bags with a gradient filtration structure. These filter bags are composed of multiple layers of glass fiber materials with different pore sizes. From the inlet to the outlet, the pore sizes gradually decrease. When the dusty gas passes through the filter bag, large particles of dust are first intercepted by the outer layer of larger pore size glass fiber materials, while small particles of dust are captured by the inner layer of smaller pore size materials. This gradient filtration structure can fully utilize the filtering advantages of different pore size glass fiber materials, achieve efficient filtration of dust of different particle sizes, reduce the accumulation of dust inside the filter bag, lower the operating resistance, and improve the cleaning effect. Moreover, some manufacturers have further enhanced the sealing performance and installation convenience of the filter bags by optimizing the sewing process and bag mouth design, thereby improving the overall performance of the products.

In terms of market application, glass fiber filter bags, due to their outstanding performance, are widely used in numerous industrial sectors. In the steel industry, during the steel smelting process, a large amount of hot and highly dusty exhaust gas is produced, which contains various metal oxides and impurities. Glass fiber filter bags can operate stably in high-temperature environments, effectively filtering the dust in this exhaust gas, ensuring compliance with emission standards, and recovering valuable metal dust to achieve resource recycling. In the cement industry, the kiln heads and kiln tails, as well as the raw material grinding and cement grinding processes, all generate a large amount of dust. Glass fiber filter bags, with their characteristics of high-temperature resistance, corrosion resistance, and high-precision filtration, have become the preferred equipment for controlling dust pollution in the cement industry, ensuring the environmental protection and sustainability of cement production. In the power industry, the flue gas produced by coal-fired boilers contains a large amount of fly ash and other particulates. Using glass fiber filter bags to filter this flue gas can significantly reduce dust emissions, reduce air pollution, and protect the normal operation of power generation equipment, thereby improving power generation efficiency. In addition, glass fiber filter bags have also been widely used in industries such as chemicals, ceramics, glass manufacturing, and waste incineration, providing effective solutions for dust pollution control in various industries.

With the increasingly strict environmental policies and the growing demand for environmental-friendly products in the market, the fiberglass filter bag market is showing a favorable development trend. On one hand, the configuration requirements for environmental protection equipment in newly-built industrial projects are constantly increasing, which prompts enterprises to increase their purchase of efficient dust removal equipment such as fiberglass filter bags. On the other hand, existing enterprises, in order to meet the increasingly strict environmental emission standards, also upgrade and replace their original dust removal equipment one after another, which brings a huge demand for renewal and upgrading in the fiberglass filter bag market. According to market research institutions’ predictions, in the coming years, the global market size of fiberglass filter bags will maintain stable growth, especially in emerging economy countries, as the industrialization process accelerates and environmental awareness improves, the prospects of the fiberglass filter bag market are broad.

However, the competition in the market has become increasingly fierce. With the growing demand for fiberglass filter bags, more and more enterprises have entered this field, making the competition even more intense. Each enterprise, in order to gain a foothold in the market, has increased investment in technological research and development, improved product quality and performance, reduced production costs, and strengthened brand building and market promotion. In this market environment, some enterprises with weaker technical capabilities and unstable product quality will face the risk of being eliminated. Therefore, for fiberglass filter bag manufacturing enterprises, how to stand out in the fierce market competition lies in continuous innovation, continuously enhancing the technical content and added value of products to meet the increasingly diverse needs of customers.

Looking ahead, with the continuous advancement of technology and the further improvement of environmental protection requirements, the fiberglass filter bag industry will embrace more development opportunities. On one hand, the continuous emergence of new technologies and materials will provide a broader space for the technological innovation of fiberglass filter bags. For instance, the application of nanotechnology and intelligent materials is expected to further enhance the performance of fiberglass filter bags, enabling new breakthroughs in aspects such as filtration accuracy, self-cleaning ability, and service life. On the other hand, as global attention to sustainable development continues to increase, green and environmentally friendly fiberglass filter bags will become the mainstream development direction in the market. Enterprises need to strengthen the research and application of environmentally friendly production processes, reduce energy consumption and pollutant emissions during the production process, and pay attention to the recyclability of products to achieve a win-win situation of economic benefits and environmental benefits.

The fiberglass filter bag, as an important equipment in the field of industrial dust removal, has a broad market prospect driven by technological innovation. However, at the same time, enterprises also need to face fierce market competition and constantly changing market demands. By continuously innovating and optimizing product performance, they can establish a foothold in the market and achieve long-term development. It is believed that with the joint efforts of all parties in the industry, the fiberglass filter bag will play a more important role in future industrial production and environmental protection.