In the metalworking industry, efficiency and precision have always been crucial indicators for measuring production levels. The emergence of the Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line has brought about a technological revolution in metal processing, redefining the standards for high-efficiency and precise production.

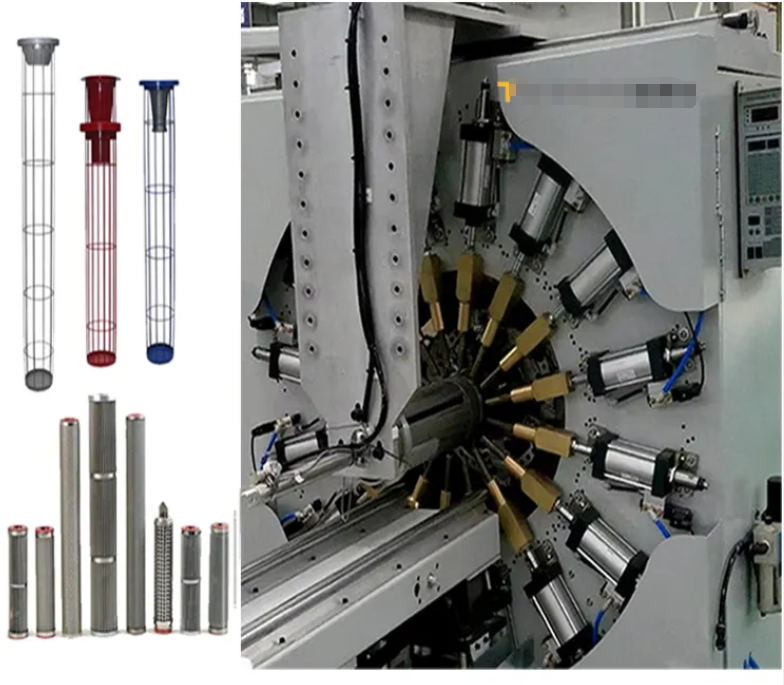

This automatic line adopts multi-head spot welding technology, significantly enhancing welding efficiency. Traditional manual welding or single-head welding equipment are time-consuming and have low production capacity when dealing with workpieces like filter cage dust collector frames that require numerous welding points.

In contrast, the multi-head spot welding automatic line can perform multiple welding points simultaneously, increasing the welding speed several times compared to traditional methods. For example, in the production of a standard filter cage dust collector frame, the multi-head spot welding automatic line can reduce the production time by more than 60%, remarkably improving the production efficiency of enterprises. This enables companies to complete order deliveries in a shorter time, enhancing their competitiveness in the market.

In terms of precision, the automatic line is equipped with advanced positioning systems and high-precision welding equipment. Through precise mechanical structures and intelligent control systems, it ensures that the position and quality of each welding point reach extremely high standards. Whether it is the spacing, depth, or strength of the welding points, they can strictly meet the design requirements, avoiding errors and quality instability caused by manual operation. This high-precision welding process not only guarantees the structural strength and stability of the filter cage dust collector frame but also improves the overall product quality, reducing the defective rate and saving a large amount of raw material and production costs for enterprises.

In addition, the Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line also features a high degree of automation and intelligence. It can achieve fully automated operations for the entire process, from workpiece feeding, positioning, welding to unloading, without the need for excessive manual intervention. Operators only need to input relevant process parameters and production instructions into the control system, and the equipment will run automatically according to the preset program. Meanwhile, the automatic line is equipped with a fault diagnosis and early warning system, which can monitor the running status of the equipment in real-time. Once a fault or abnormal situation is detected, it will immediately issue an alarm and stop running, facilitating maintenance personnel to conduct repairs in a timely manner and ensuring the normal operation of the equipment and production safety.

In today’s highly competitive metalworking market, the Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line, with its advantages of high efficiency, precision, and automation, has become an important choice for many enterprises to improve production levels and economic benefits. Its emergence not only promotes the technological progress of the metalworking industry but also provides strong support for enterprises to achieve intelligent and automated production.

Post time: May-27-2025