Products

-

Industrial dust removal equipment electromagnetic pulse valve Y-12 inch

Industrial dust removal equipment electromagnetic pulse valve Y-12 inch

UndernormalserviceconditionToguaranteethesafetyandreliability,theelectromagneticpulsevalveshallbeoperatedundertheallowableconditionandinaccordancewiththistheoperatinginstruction.Otherwise,alllossesordamagesarisingfromitwillbeassumedbyuser.Iftheuserfalsifiestheelectromagneticpulsevalve,ormodifiesitwithoutauthorization,ordoesn’tcomplywiththeoperatinginstruction,thewarrantywillbeinvalid,andwewillnotberesponsiblefortheproduct.Theelectromagneticpulsevalvecannotbeusedinfluidsthatmaycausechemicalerosionormechanicaldamagetomaterialsofthevalve.Ifthereisnoexactempiricalvalueshowingitsapplicability,youhadbetterfollowtheInstructionManual.Theoperatinginstructionispartoftheproductandshallbesafeandvalidwithintheservicelifeoftheproduct.SafetymeasuresThesemeasuresarerelatedwithsingleelectromagneticpulsevalveonly.Ifthevalveiscombinedwithotherpartsofequipment,itmayhaveotherpotentialdangers,sotheyshallbeconsideredthroughriskanalysisonthesystem.

-

Industrial filter bag efficient dust removal, factory custom

Industrial filter bag, dust filter, liquid filter bag, high temperature filter bag, customized filtration solution, environmental protection filtration equipment

Industrial filter bag has the characteristics of high strength, acid and alkali corrosion resistance, wear resistance, folding resistance, easy to clean ash, water repellant oil, anti-static and so on. Application: Industrial filter bags are widely used in steel, cement, chemical industry, power plants, road construction, metallurgy, grain processing, electronics, tobacco and other environmental protection projects

-

Why choose our industrial filter bags?

Why choose our industrial filter bags

** Super durability ** : Select high temperature resistance, corrosion resistance materials (such as polyester, polypropylene, PTFE), to adapt to acid, high temperature, high pressure environment, life extension of more than 30%.

✅ ** Multi-scenario adaptation ** : Covering chemical industry, food processing, pharmaceutical, metallurgy, cement, water treatment and other industry needs, tailored filtration solutions.

✅ ** Energy saving ** : low pressure difference design reduces energy consumption, high pollution capacity reduces replacement frequency, and the overall cost drops by 20%.

✅ ** Safety compliance ** : In line with ISO, FDA and other industry standards, non-toxic and pollution-free, to help you easily pass the environmental audit. -

Customized PP PPS and PTFE mixture dust air filter bag

Customized PP PPS and PTFE mixture dust air filter bag

1-5m long for dust removal and filtration matcth bag filter cage

The filter bags produced by our company are designed for harsh industrial environments, using multi-layer composite filter materials and high precision process to effectively intercept micron particles, filtering efficiency of up to 99.9%! Whether it is dust, oil, chemical particles or liquid impurities, it can be easily handled to ensure that the production process is clean and worry-free.

-

Customized bleached cotton wound dust filter PP 1-200um

Customized bleached cotton wound dust filter PP 1-200um used to remove suspended solids in liquids acid and alkali resistance

AFC– filter cartridge bleached cotton 50 -200micron1- 3.5″ Dia. x 30″ L string wound filter cartridge with a tinned steel core. Bleached cotton string wound cartridges work well for potable liquids, vegetable oils, beverages, organic solvents and more. The bleached cotton is FDA acceptable under CFR title 21 for food and potable water contact. This 50 micron filter cartridge is double open ended (DOE) with no caps

-

Factory dust removal equipment accessories Hot selling products dust removal filter bag

Factory dust removal equipment accessories Hot selling products dust removal filter bag

Polyester needle felt waterproof, oil-proof and electrostatic filter bag.

Our company polyester needle filter felt selection of 1-2.5D polyester fine denier, with high strength and low elongation yarn woven reinforced base cloth, through the needle reinforcement and post-treatment technology. In addition to the characteristics of high porosity, good permeability, acid resistance and moderate alkalinity of ordinary felt filters, the product has very good wear resistance, so it is a variety of felt filters widely used. G weight from 350g/m2-800g/m2, thickness from 1mm-4mm our factory can produce. The post-treatment methods are calendering, singeing, heat setting, impregnation drying, coating and so on. It has the characteristics of stable size, easy cleaning and long service life.The surface smoothness of filter material has a great influence on the dynamic running resistance of filter material. The initial resistance of the filter material is determined by the permeability of the filter material itself, and the resistance in operation is many times larger than the initial resistance. The running resistance depends on the smoothness of the filter surface and the cleaning effect. It is generally hoped that when the filter material ensures the same filtration efficiency, the larger the air permeability, the better, that is, the lower the resistance, the better, because this can save a lot of energy. In the dust collector with air flow back blowing, when the air flow of the same pressure and the same air volume is used for dust removal, the dust removal effect of the woven fabric with high air permeability is better than that of the woven fabric with low air permeability. Therefore, in the case of ensuring the high filtration accuracy of the filter material, how to improve the permeability of the filter material and improve the surface smoothness, reduce dust adhesion, and reduce the operating resistance is the first topic that the filter material manufacturer should study. The air permeability of the surface resinized smooth finishing needled filter felt developed by our factory is more than 50% higher than that of ordinary calender finishing filter material, and the surface smoothness is more smooth than that of calender finishing.

-

Diaphragm kit for solenoid valve 1 1/2 inch Electromagnetic pulse valve

Factory customization diaphragm kit for solenoid valve 1 1/2 inch Electromagnetic pulse valve diaphragm nylon material

Product name Diaphragm kits for pulse valve Materials NYLON Temperature Resistance max -40 to 80 degree Size (mm) 66 mm& 200mm Specification Z-40S Diameter mm 100-200mm Thickness mm 3.1m Type 1.5inch embedded type Used for Installed on the pulse valve -

High quality Acrylic Filter Bag filter bag for industrial dust removal Industrial Filter Bag Price

High quality Acrylic Filter Bag filter bag for industrial dust removal Industrial

Acrylic Filter Bag filter bag

Our producted manufactures high performance homopolymer acrylic filter bags and provides reliable filtration solutions. Customized sizes are available In addition to the standard sizes.

Material : 100% Acrylic staple fiber.

Scrim: With Acrylic staple yarn.

Length & diameter: No limited.

Weight: 300 -600g/m2 ±10%.

Temperature (℃/℉): Continue: 120/248, Instant: 140/284.

Finish-treatment: Calendering, Heat setting, Singeing.

Anti-acid and alkali: PH ranges from 3-11.

Filtration Efficiency: Reach to 99.5%.

Stable working time: Up to more than 3000 hours. Could be used cyclically. -

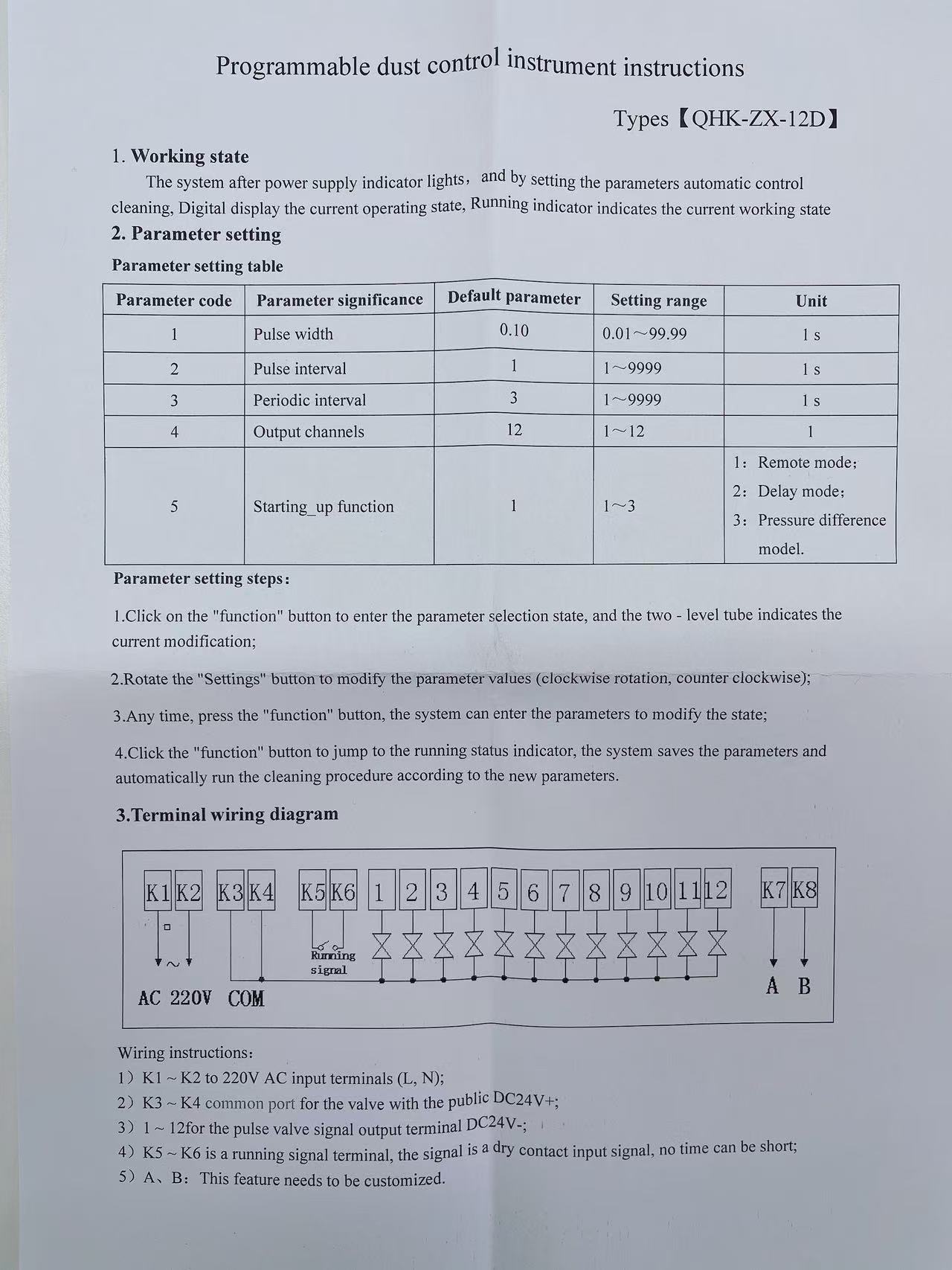

High quality QHK-ZX-12D pulse controller

Dust Removal Equipment Controller: Precision and Efficiency Redefined

The dust removal equipment controller is a vital component in modern dust control systems, designed to ensure optimal performance and efficiency.

Advanced Control Functions

It comes equipped with a range of advanced control features. With precise timing control, it can accurately regulate the operation time of each component in the dust removal equipment, such as the start and stop times of the dust collector and the vibration device for dust cleaning. This ensures that the dust removal process is carried out in an orderly and efficient manner. In addition, it has intelligent pressure monitoring. By continuously monitoring the pressure difference in the dust removal system, it can promptly detect any blockages or abnormal situations and take corresponding measures to maintain the stability of the system.User – Friendly Interface

Featuring a user – friendly interface, the controller is easy to operate and configure. The intuitive display screen shows real – time operating data, including dust concentration, equipment running status, and alarm information. Operators can easily set parameters and adjust operating modes through the simple control buttons, making it convenient for both experienced technicians and novice operators to use.High Reliability and Stability

Built with high – quality components and advanced circuit design, the controller offers excellent reliability and stability. It can operate stably in harsh industrial environments with high temperatures, high humidity, and strong electromagnetic interference. Its robust construction ensures minimal downtime and low maintenance costs, providing a reliable guarantee for the long – term operation of the dust removal equipment.Versatile Compatibility

This controller is highly versatile and compatible with a wide variety of dust removal equipment, including bag filters, electrostatic precipitators, and wet scrubbers. It can be easily integrated into different dust control systems, meeting the specific needs of various industries such as cement, steel, and power generation.In summary, the dust removal equipment controller is a high – performance, reliable, and user – friendly device that plays a crucial role in improving dust removal efficiency, reducing environmental pollution, and ensuring the smooth operation of industrial production.

-

High – Performance Liquid Filter Bags: Your Ideal Filtration Solution

High – Performance Liquid Filter Bags: Your Ideal Filtration Solution

In industrial and commercial liquid – handling processes, efficient filtration is not just a luxury but a necessity. Our liquid filter bags are engineered to meet and exceed the highest standards of filtration performance.

Product name: polyester filter bag

Filter material: polyester

Filter bag pressure: pressure difference ≤ 0.2MPa (replacement filter bag reference value)

Project

Skills Requirement

Detect

Determination

Gram weight (g/mg²)

500(±5%)

512

Qualified

Thickness (mm)

2.3(±5%)

2.35

Qualified

Air permeability

(L/m².s)

350-500(±25)

370

Qualified

Breaking Strength

(N)

warp

800(±2%)

803

Qualified

weft

1100(±2%)

1125

Elongation

warp

35(≤%)

34

Qualified

weft

50(≤%)

48

Temperature resistance(°C) ≤130(°C)

127°C

Qualified

Exterior No wrong warp, wrong weft, broken edges, smudges, scratches and holes

No wrong warp, wrong weft, broken edges, smudges, scratches and holes

Qualified

The fabric has passed the sanitary standard and testing standard:GB4806.7-2016

Processing technology: all seams, O- galvanized ring

PEΦ180*430*5UM 880 pcs

After passing the inspection, it will be given out of the factory and hereby certified.

Superior Filtration Precision

Available in a wide range of micron ratings, from ultra – fine to coarse filtration, our filter bags can effectively remove particles, impurities, and contaminants of various sizes. Whether it’s in the chemical, food and beverage, pharmaceutical, or water treatment industries, they ensure that your liquid products meet the strictest quality requirements.Exceptional Durability

Made from high – quality materials, these filter bags are designed to withstand the rigors of continuous use. They resist corrosion, abrasion, and chemical degradation, ensuring a long service life and reducing the frequency of replacement. This durability not only saves costs but also minimizes downtime in your production processes.Easy Installation and Maintenance

Our liquid filter bags are designed for quick and hassle – free installation. They fit seamlessly into most standard filter housings, allowing for easy integration into your existing filtration systems. Additionally, maintenance is a breeze. When the filter bag reaches the end of its service life, it can be easily removed and replaced, keeping your operations running smoothly.Cost – Effective Filtration

By providing high – quality filtration at a competitive price, our filter bags offer an excellent cost – performance ratio. Their long – lasting performance and easy maintenance contribute to overall cost savings, making them a smart investment for any business looking to optimize its filtration processes.Choose our liquid filter bags and experience the difference in filtration efficiency, durability, and cost – effectiveness. Contact us today to find the perfect filtration solution for your specific needs.

-

filter bag for industrial dust removal,Nomex needle-felt 500gsm with PTFE membrane,

Hot sale, filter bag for industrial dust removal,Nomex needle-felt 500gsm with PTFE membrane, Industrial Filter Bag Price, Manufacture Filter Bag;

The company specializes in providing filter bags, dust filter bags, dust cloth bags, high temperature filter bags,PPS filter bags and other products; Welcome to inquire about dust filter bag, the company has strong technical force, complete product varieties.

-

Dust Collector Polyester PPS 500gsm Dust Filter Bag

Hot sale, High quality Filter Bag filter bag for industrial dust removal.Dust Collector Polyester PPS 500gsm Dust Filter Bag, Industrial Filter Bag Price, Manufacture Filter Bag

AASF is your best partner who offers complete Solution for Bag Filtration Equipment, a comprehensive package that includes all the necessary components and services for bag filtration systems. It typically includes the bag filter housing, filter bags, filter cartridges, filter media, and any additional accessories required for installation and operation. The solution also includes technical support, maintenance services, and training for the proper use and maintenance of the equipment.

The main products of the Company include electromagnetic pulse valves, pulse jet controllers, bag filters, bag filter cages, special parts, etc. these are wildly used in Cement, Mills, Asphat, Boilers, Chemical processing etc. Our company gains a domestic and global reputation for long time with many loyal customers.