Products

-

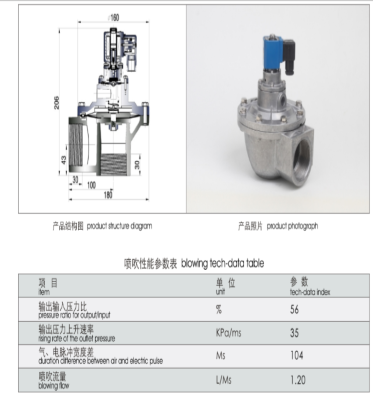

DMF-ZM-40S pilot coil air electromagnetic diaphragm pulse valve

High quality air through solenoid valve Air electromagnetic diaphragm pulse valve for dust collector,DMF-ZM-40S pilot coil air electromagnetic diaphragm pulse valve

high pressure gas enters the lower gas chamber from the air intake port. When there is no power, the gas enters the decompren chamber through the constant pressure pipe and throttle hole.

When electricity is generated, the spool is lifted by the electromagnetic force, the pressure relief hole is opened, the pressure of the decompression chamber is lower than that of the lower gas chamber, and the gas in the lower gas chamber lifts up the diaphragm and opens the nozzle for spraying.

The spool blocks the pressure relief hole under the action of the spring, and the diaphragm blocks the nozzle.

ABOUT US

AASF is your best partner who offers complete Solution for Bag Filtration Equipment, a comprehensive package that includes all the necessary components and services for bag filtration systems. It typically includes the bag filter housing, filter bags, filter cartridges, filter media, and any additional accessories required for installation and operation. The solution also includes technical support, maintenance services, and training for the proper use and maintenance of the equipment.

The main products of the Company include electromagnetic pulse valves, pulse jet controllers, bag filters, bag filter cages, special parts, etc. these are wildly used in Cement, Mills, Asphat, Boilers, Chemical processing etc. Our company gains a domestic and global reputation for long time with many loyal customers.

-

Compressed air switch for dust removal in cement plant,DMF-ZM-25

Compressed air switch for dust removal in cement plant,DMF-ZM-25 pilot coil air electromagnetic diaphragm pulse valve.

Right-angle pulse valve: high pressure gas enters the lower gas chamber from the air intake port. When there is no power, the gas enters the decompression chamber through the constant pressure pipe and throttle hole. The spool blocks the pressure relief hole under the action of the spring, and the diaphragm blocks the nozzle. When electricity is generated, the spool is lifted by the electromagnetic force, the pressure relief hole is opened, the pressure of the decompression chamber is lower than that of the lower gas chamber, and the gas in the lower gas chamber lifts up the diaphragm and opens the nozzle for spraying.

About us

AASF is your best partner who offers complete Solution for Bag Filtration Equipment, a comprehensive package that includes all the necessary components and services for bag filtration systems. It typically includes the bag filter housing, filter bags, filter cartridges, filter media, and any additional accessories required for installation and operation. The solution also includes technical support, maintenance services, and training for the proper use and maintenance of the equipment.

-

Right-angle pulse valve,Hot selling product Industrial dust removal parts

Right-angle pulse valve DMF-Z-40S :

high pressure gas enters the lower gas chamber from the air intake port.

When there is no power, the gas enters the decompression chamber through the constant pressure pipe and throttle hole. The spool blocks the pressure relief hole under the action of the spring, and the diaphragm blocks the nozzle. When electricity is generated, the spool is lifted by the electromagnetic force, the pressure relief hole is opened, the pressure of the decompression chamber is lower than that of the lower gas chamber, and the gas in the lower gas chamber lifts up the diaphragm and opens the nozzle for spraying.

-

Factory customized P84 with PTFE membrane Industrial dust filter bag for industrial dust removal

A new choice for industrial dust removal, PTFE dust removal filter bag

In the complex environment of industrial production, dust pollution is a thorny problem, which not only affects the quality of products, but also threatens the health of employees and damages the ecological environment. PTFE dust filter bag with excellent performance, to provide you with the perfect solution.

PTFE material chemical stability is strong, can resist a variety of acid and alkali and chemical substances erosion, suitable for chemical industry, metallurgy and other corrosive production environment. High temperature resistance is also very good, can work stably at 260℃ high temperature, to ensure efficient filtration under high temperature conditions.

Its filtration accuracy is extremely high, and the filtration efficiency of fine dust is over 99.9%, which can effectively intercept PM2.5 and even finer particles, helping enterprises to easily meet environmental protection emission standards. At the same time, PTFE surface is smooth, dust is not easy to adhere, ash removal is easy, can greatly extend the service life, reduce the frequency of replacement and maintenance costs.

PTFE dust filter bag is a high-quality choice to improve production efficiency, reduce operating costs, and protect the ecological environment. Let us join hands to protect the blue sky with science and technology and create a green future!

-

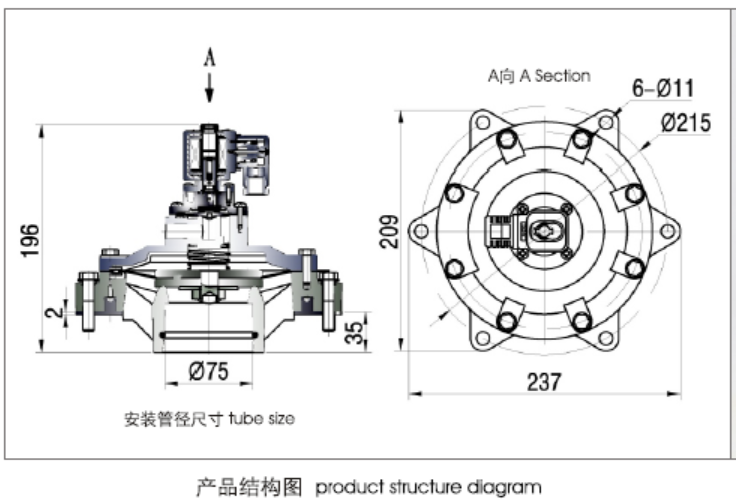

Industrial Dust Removal Equipment Pulse Valve DMF-Y-62S

Submerged pulse valve DMF-Y-62S:

the structure is similar to the right Angle pulse valve, no air inlet, directly to the air bag as the lower air chamber. The diaphragm divides the valve into the front and rear air chambers.

When the compressed air is connected, the pressure of the rear air chamber makes the diaphragm close to the valve outlet and is closed. The pulse injection controller sends out an electrical signal to make the electromagnetic pulse valve armature move back, the rear air chamber release hole open, the diaphragm moves back, and the compressed air is sprayed through the valve outlet.

-

Industrial dust removal equipment pulse valve DMF-Z-20

Right-angle pulse valve DMF-Z-20:

high pressure gas enters the lower gas chamber from the air intake port. When there is no power, the gas enters the decompression chamber through the constant pressure pipe and throttle hole. The spool blocks the pressure relief hole under the action of the spring, and the diaphragm blocks the nozzle. When electricity is generated, the spool is lifted by the electromagnetic force, the pressure relief hole is opened, the pressure of the decompression chamber is lower than that of the lower gas chamber, and the gas in the lower gas chamber lifts up the diaphragm and opens the nozzle for spraying.

peculiarity

• High efficiency ash removal: The dust on the cloth bag can be quickly removed by the method of pulse blowing ash removal, and the dust removal efficiency can be improved.

• Extend the service life of the bag: regular cleaning can prevent the bag from being damaged due to the accumulation of too thick dust and extend its service life.

• Stable operation: Using automatic control, stable and reliable operation, and the entire cleaning process has a high degree of automation, reducing manual intervention and improving production efficiency.

-

customized dust air filter bag

Popular matching customized dust air filter bag Filtration Polyester needle felt for cement plant and power plant.

ndustrial dust filter bag is the key component of industrial dust removal equipment.

It is mainly used to capture solid particles such as dust produced in the industrial production process. Generally, it is a cylindrical bag-like fabric with a variety of materials, including polyester fiber, polypropylene, aramong and so on. The filter bag made of polyester fiber has good acid and alkaline resistance and can resist chemical erosion to a certain extent; The aramid material has high strength and high temperature resistance, which is suitable for high temperature working environment.

The working principle of the filter bag is that after the dust-containing gas enters the bag dust collector, the dust with larger particles settles first under the action of gravity, and then the gas passes through the filter bag, the dust is intercepted on the surface of the filter bag, and the clean gas is discharged. Its filtration accuracy varies depending on the material and process, and it can effectively filter micron level particles, so as to achieve the purpose of purifying the air.

-

Dust removal framework

Professional custom manufacturer direct sales industrial dust collector bag dust filter bag can be processed and customized according to requirements

Professional customization of industrial dust collector accessories such as dust removal bags, pulse controllers, pulse valves, and dust removal skeletons

Dust removal frame, also known as dust removal bag cage, is an essential accessory of bag filter, used as a frame to support the dust removal filter bag. It can be compatible with six, eight, ten, twelve, sixteen, eighteen, twenty, and twenty-four ribs. The role of dust removal frame is very important and it is widely used in the dust removal industry, chemical industry, and other industrial places.

Shape:

(External filter type) (elliptical, diamond shaped)

Envelope type

Multi section frame (elliptical multi section frame, circular bag type multi section frame (plug-in, chuck type))

Finished frame (frame with Venturi tube, frame packaged in plastic bags or iron frames, neatly arranged diamond frame)

Specifications

rotundity ellipse. Flat shape Envelope shaped trapezoid. Star shaped Spring type other customized dust removal skeletons of various models according to customer requirements

Raw material: High quality low-carbon steel wire Galvanized steel wire Stainless steel wire, etc

Surface treatment: Galvanized Spray painting Anti corrosion treatment Surface organic silicon spraying, etc The surface organic silicon coating is particularly suitable for dust collector applications in large generator sets -

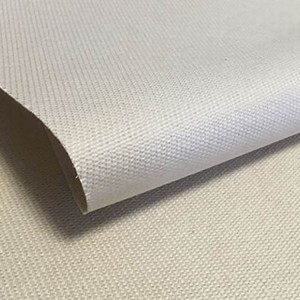

Acrylic needle felt filter cloth

Parameters Parameters Representation Reference Information parameters Product Name Fiberglass Polyester needle felt 750g/m² Product Code FB-PE750-MIT Physical properties Weave method needle felt Thickness 2.5 Weight 750 g/m² Width 1.8m-2.2m Loss on Ignition (%) ≥10 Chemical Finish PTFE impregnation Air Permeability (L/m²S@200Pa) 30- 100 Tensile strength( N/5cm ) Warp 1300 Weft 1500 Tensile elongation(%) Warp 8 Weft 8 Temperatu... -

Anti-Static Needle Felt Cloth

Parameters Parameters Representation Reference Information parameters Product Name Anti-Static Needle Felt Cloth Product Code AASF-PE550 AS Cloth Physical properties Weave method needle felt Thickness 2.0±0.08 Weight 550 g/m² Width 1.8m-2.1m customizing Loss on Ignition (%) ≥10 Chemical Finish PTFE coating Optionally Air Permeability (L/m²S@200Pa) 30- 80 Tensile strength( N/5cm ) Warp ≥1200 Weft ≥1300 Tensile elongation(%) Warp ≤35 ... -

Fiberglass cloth

The fiberglass is an inorganic fiber whose main component is SiO2. It is obtained by melting the glass frit at a temperature of 1300-1600 ° C, drawing filaments from the molten state and rapidly quenching. There are two kinds of filter materials: C glass (medium-alkali glass or soda calcium silicate glass) and E glass (alkali-free glass or aluminoborosilicate glass). The most advantages of fiberglass is high temperature resistance, good dimensional stability, and high tensile breaking strength. In terms of chemical corrosion resistance, glass fiber is stable to other media except hydrofluoric acid and high temperature and strong alkali. The fiberglass filter bag is resistant to high temperature, abrasion, water and oil.

-

Nomex Cloth

Nomex/Aramid needle punched felt is one of the most common materials used to make filter bags. And it is not flammable nor ignition, suitable for high temperature environment. Nomex/Aramid Properties Material Working Instant Temperature Abrasion Resistance Hydrolysis Resistance Acid Resistance Alkali Resistance Oxidation Resistance Temperature Aramid Needle Felt 220℃ 240℃ Good Middle Middle Good Middle Product name Aramid needle felt 550g/m² with PTFE membrane Prod...