Products

-

Explore the Superiority of Filter Bags: Your Key to High – Efficiency Filtration

Filter bags are the unsung heroes in the world of filtration, providing efficient and reliable solutions for countless applications. Their significance lies in their ability to deliver high – quality filtration, making them essential in both daily life and industrial operations.

In the food and beverage sector, filter bags are vital for producing top – notch products. When making soy milk, filter bags separate the soybean residue, leaving behind a smooth and nutritious drink. In the production of fruit juices, they remove unwanted pulp, enhancing the clarity and taste. In the industrial field, filter bags are used in a wide array of processes, from the purification of chemicals to the treatment of industrial fluids. They effectively remove particulate matter, ensuring the smooth progress of production and the quality of end – products. In environmental applications, filter bags are crucial for purifying wastewater, playing a key role in environmental protection.The materials of filter bags determine their performance and suitability for different tasks. Nylon filter bags are strong and resistant to chemicals and wear, making them suitable for harsh industrial environments. Cotton filter bags, with their natural and safe properties, are favored in food – processing scenarios. Non – woven filter bags combine affordability with good filtration efficiency, making them popular in many household and commercial applications. Other materials like polyester, stainless steel, and polytetrafluoroethylene offer specialized features for specific filtration requirements.The design of filter bags is optimized for maximum performance. The precisely engineered mesh structure ensures efficient particle removal. Advanced manufacturing methods, like the hot – melt process for non – woven bags and precision sewing techniques, guarantee reliable performance and prevent leakage. Attention to detail, such as the use of removable labels, shows the commitment to maintaining the purity of the filtrate. Filter bags with high – precision metal rings provide a secure fit, reducing the chances of side leakage.Maintenance of filter bags is straightforward, and their long – lasting nature makes them a cost – effective choice. Regular cleaning can restore their filtration ability, and their durability means less frequent replacement. The wide range of sizes and specifications of filter bags allows users to select the most suitable option for their specific needs. Whether you are a home cook, a small business owner, or a large – scale manufacturer, filter bags can meet your filtration requirements. Choose filter bags for a cleaner, purer, and more efficient filtration experience. -

Filter Bags: Unrivaled Filtration Solutions for Diverse Industries

Filter Bags: Unrivaled Filtration Solutions for Diverse IndustriesIn the modern world, where precision and purity are highly valued, filter bags have emerged as indispensable tools across a multitude of industries. These versatile filter bags play a crucial role in ensuring the quality of products and safeguarding the environment by efficiently removing impurities and contaminants.Filter bags find extensive applications in various sectors. In the food industry, filter bags are essential for maintaining the hygiene and taste of food products. Whether it’s the production of beverages like fruit juices and soy milk, or the refining of edible oils, filter bags with their fine – meshed structure can effectively separate residues such as fruit pulp and soybean dregs, guaranteeing a pure and delightful taste. In the industrial realm, filter bags are utilized for the purification of chemical raw materials, filtration of electroplating solutions and paints. High – performance filter bags, such as the BMN series, can provide precise micron – level filtration, meeting the stringent requirements of critical industrial applications. In environmental protection, filter bags contribute significantly to wastewater treatment, helping to separate solid impurities and promoting the recycling of water resources.The diverse range of materials used in filter bags offers unique advantages. Nylon filter bags are renowned for their excellent abrasion resistance and chemical stability. They can withstand high – temperature environments and are ideal for filtering liquids containing particulate impurities, widely used in industrial liquid filtration. Cotton filter bags, made from natural materials, are environmentally friendly and possess superior breathability and moisture absorption, making them perfect for food – related applications. Non – woven filter bags are cost – effective and highly efficient in filtration. They are commonly applied in air filtration, traditional Chinese medicine decoction, and tea – making, effectively filtering out dust and other impurities. Additionally, filter bags made of polyester, stainless steel, and polytetrafluoroethylene also shine in different working conditions, meeting diverse filtration needs.In terms of design and manufacturing, filter bags showcase outstanding craftsmanship. The high – density mesh design enhances filtration efficiency, enabling the capture of even the tiniest particles. Advanced manufacturing techniques, such as hot – melt bonding for non – woven filter bags and high – speed industrial sewing without silicone oil for stitched filter bags, ensure leak – proof performance and prevent contamination of the filtrate. Special attention is also paid to details like removable product labels to avoid any potential pollution. Some filter bags are equipped with stainless – steel collars or galvanized steel rings, which, through argon – arc welding technology, achieve high – precision dimensions, improving the sealing degree and reducing the risk of leakage.Filter bags are not only efficient but also easy to maintain and cost – effective. Most filter bags can be cleaned simply by shaking or rinsing after use. For stubborn stains, appropriate cleaning methods can be adopted according to the material. Their durability means fewer replacements, reducing overall costs. With a wide variety of sizes and specifications available, filter bags can perfectly adapt to different user requirements, from small – scale home use to large – scale industrial production. In conclusion, filter bags are the go – to choice for high – quality filtration, offering reliable solutions for various industries. -

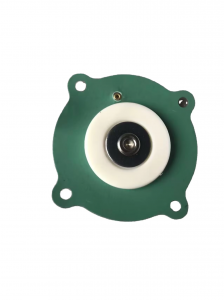

Analysis of the Function of Diaphragms in Electromagnetic Pulse Valves

In the complex pneumatic systems of modern industry, although the diaphragms of electromagnetic pulse valves may seem insignificant, they play a crucial role. The quality of their performance directly affects the operational efficiency and stability of the entire system. A thorough exploration of the functions of diaphragms in electromagnetic pulse valves helps us better understand the operating mechanisms of industrial equipment.From the perspective of working principles, the diaphragm of an electromagnetic pulse valve is the core component for achieving precise control. When the electromagnetic coil of the electromagnetic pulse valve is energized, an electromagnetic force is generated, attracting the diaphragm to overcome the spring force and back pressure. The diaphragm deforms instantaneously, opening the valve port, allowing compressed air to rapidly pass through the pulse valve into the blowpipe and jet out at high speed in an extremely short time, performing a powerful cleaning of the filter bags in dust collectors. When the electromagnetic coil is de-energized, the electromagnetic force disappears, and the diaphragm quickly resets under the action of the spring force and back pressure, closing the valve port and cutting off the air flow. In this process, the diaphragm acts like an accurate “commander,” controlling the on-off of the air flow through its own deformation and resetting, achieving precise operation of the pulse injection.In dust collection systems, the role of the diaphragm in electromagnetic pulse valves is particularly critical. Take bag dust collectors as an example. As the dust collection work continues, dust will continuously adhere to the surface of the filter bags, increasing resistance and affecting dust collection efficiency. At this time, the pulse injection system controlled by the diaphragm of the electromagnetic pulse valve comes into play. Through an instantaneous high-pressure injection, it removes the dust on the surface of the filter bags, restoring the air permeability of the filter bags and ensuring the long-term stable operation of the dust collector. The rapid response and reliable sealing performance of the diaphragm ensure that each injection is accurate and efficient, extending the service life of the filter bags and reducing maintenance costs. Statistics show that in dust collection systems using electromagnetic pulse valve diaphragms with good performance, the replacement cycle of filter bags can be extended by 30% – 50%.In addition to the dust collection field, diaphragms of electromagnetic pulse valves are also widely used in other industrial scenarios. In industries with extremely high hygiene requirements, such as food and pharmaceuticals, pneumatic conveying systems often use electromagnetic pulse valves to control the conveying of materials. The good sealing and corrosion resistance of the diaphragm can effectively prevent material leakage and contamination, ensuring product quality and safety. In automated production lines of industries such as automotive manufacturing and mechanical processing, diaphragms of electromagnetic pulse valves are used to control the actions of cylinders, enabling precise grasping, handling, and assembly of components. Their fast switching actions and stable performance improve the degree of automation and production efficiency of the production lines.With its unique function of controlling air flow, the diaphragm of the electromagnetic pulse valve plays an indispensable role in the industrial field. With the continuous development of industrial technology, the performance requirements for diaphragms of electromagnetic pulse valves are also increasing day by day. In the future, they will develop towards a more efficient, reliable, and intelligent direction, continuing to escort industrial production. -

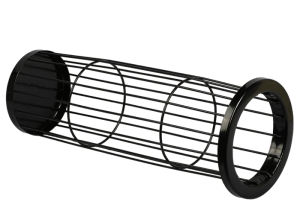

Working Principle of the Dust Removal Filter Cage

In modern industrial production, dust pollution is a problem that cannot be ignored. It not only poses a threat to the health of workers but also has a negative impact on the environment. To address this issue, various dust removal devices have emerged, and the dust removal filter cage, as a key component among them, is quietly playing an important role, serving as the invisible guardian of industrial environmental protection.

I. Working Principle of the Dust Removal Filter Cage

The working principle of the dust removal filter cage is based on the basic mechanism of filtration interception. When the dusty gas passes through the dust removal equipment, it first enters the area of the filter bag supported by the dust removal filter cage. The filter bags are usually made of fibrous materials with fine pores, such as polyester fibers and glass fibers. Large particles of dust are directly impacted by inertia and land on the surface of the filter bag, being intercepted by it. While the fine dust particles follow the airflow and penetrate into the interior of the filter bag, they gradually deposit on the surface of the filter bag, forming a layer of initial dust. As the dust accumulates continuously, this initial layer becomes denser and more porous, and its filtration efficiency also increases accordingly, ultimately achieving a dust removal efficiency of up to 99% or more.

During this process, the dust removal filter cage plays a crucial supporting role. It ensures that the filter bags maintain a stable shape under the impact of the airflow and the load of dust, avoiding the collapse or deformation of the filter bags, thereby maintaining the filter area without reduction and maintaining efficient dust removal effects. At the same time, the reasonable design of the dust removal filter cage structure enables the airflow to be evenly distributed on the surface of the filter bags, avoiding excessive local flow velocity that leads to dust accumulation and blockage on the filter bags, further improving the filtration efficiency and the service life of the filter bags.

-

Dewatering Filter Bag for Removing Sediment and Pollutants

A dewatering filter bag is a filtration component specifically designed to separate solid sediments, suspended matter, and pollutants from liquids, widely used in industrial wastewater treatment, municipal sludge dewatering, mining tailings processing, and other scenarios. Its core function is to achieve solid-liquid separation through efficient interception and dewatering, reducing the solid content in liquids or minimizing sludge volume.I. Core Characteristics and Working Principle

1. Key Materials and Structure

- Materials:

- Primarily made of polypropylene (PP) or polyester (PET) fibers, offering acid-alkali resistance and wear resistance;

- Special scenarios (e.g., high temperature, strong corrosion) may use nylon (PA) or polytetrafluoroethylene (PTFE).

- Structural Design:

- Multi-layer composite filter cloth: Coarse outer layer intercepts large particles, while a fine inner layer captures tiny impurities to improve dewatering efficiency;

- High-strength stitching: Reinforced stitching on bag openings and edges prevents tearing during filtration.

2. Working Principle

- Filtration Stage: Sewage containing sediments enters the filter bag, where solid particles are trapped by the filter cloth, and water drains through the cloth pores;

- Dewatering Stage: External forces (e.g., pressure, vacuum, or gravity) squeeze the bag to further extract water from between particles, forming a filter cake with a moisture content of 50–80% (depending on the application).

II. Main Application Scenarios

1. Industrial Wastewater Treatment

- Scenarios: Heavy metal ion precipitates (e.g., copper hydroxide, iron hydroxide), slag particles in wastewater from chemical, metallurgical, and electroplating industries;

- Role: Reduces SS (suspended solids) concentration in wastewater to meet subsequent treatment or discharge standards, while recovering valuable metal particles.

2. Municipal and Environmental Engineering

- Scenarios: Sludge thickening tanks in wastewater treatment plants, river dredging slurry, construction piling wastewater, etc.;

- Role: Rapidly separates water from slurry, reducing sludge volume (volume reduction ratio up to 3:1) and lowering transportation and disposal costs.

3. Mining and Quarrying Industry

- Scenarios: Dewatering of tailings slurry, ore washing wastewater treatment, mine pit drainage purification, etc.;

- Role: 截留 ore particles and heavy metal pollutants, enabling water recycling and reducing environmental risks in tailings ponds.

4. Food and Chemical Industries

- Scenarios: Separation of fruit pulp residues in food processing wastewater, crystallization products in chemical reactions, etc.;

- Role: Recovers solid raw materials (e.g., starch, sugar residue) while purifying wastewater.

III. Key Selection Parameters

1. Filtration Precision and Pore Size

- Precision Range: Typically 5–200 microns, matched to sediment particle size:Pore Size Distribution: Choose surface filtration (uniform pores) or deep filtration (gradient pores). The former suits uniform particle 污水,while the latter fits complex water with multiple particle sizes.

- Coarse particles (e.g., sand): 50–200 microns;

- Fine suspended matter (e.g., colloids): 5–50 microns.

2. Dewatering Performance Indicators

- Water Permeability: Water flux per unit filter cloth area (L/m²·h). Higher permeability speeds up filtration but requires balancing with interception efficiency;

- Water Retention: The ability to retain water in the filter cake. Poor water retention improves dewatering efficiency (e.g., when used with flocculants).

3. Pressure Resistance and Strength

- Operating Pressure: Matches the pressure type of dewatering equipment (e.g., plate-and-frame filter presses can reach 0.6–1.0MPa, while vacuum filtration uses negative pressure);

- Tear Resistance: Select filter cloth with warp and weft tensile strength ≥1500 N/m to avoid damage under high pressure.

4. Chemical Compatibility

- pH Tolerance:Solvent Resistance: Choose PET or PTFE for oily wastewater to prevent PP from swelling and damaging.

- PP material: Suitable for pH 1–14 (resistant to strong acids and alkalis);

- PET material: Suitable for pH 4–10 (resistant to weak acids and alkalis, not concentrated acids).

IV. Supporting Equipment and Processes

1. Common Dewatering Equipment

- Plate-and-Frame Filter Press: Exerts hydraulic pressure to squeeze filter bags, suitable for high-concentration slurry dewatering with low filter cake moisture content (≤60%);

- Vacuum Filter: Uses negative pressure to suction water, suitable for fine-particle sludge with high processing efficiency but higher energy consumption;

- Centrifugal Filter: Separates solid-liquid via centrifugal force, suitable for uniform particle sediments with small footprint.

2. Pretreatment Processes

- Flocculant Addition: Adds polyaluminum chloride (PAC) or polyacrylamide (PAM) to sewage to agglomerate fine particles into large flocs, improving filter bag interception efficiency and dewatering speed;

- Pre-Filtration: Uses coarse filter bags (e.g., 200 microns) to remove large particles, protecting fine filter bags and extending service life.

V. Maintenance and Environmental Considerations

1. Maintenance Tips

- Cleaning Frequency:Damage Inspection: Regularly check stitching and the bottom of the bag, and replace promptly if damage is found to prevent material leakage.

- Reusable filter bags: Backwash with high-pressure water after each dewatering to remove residual particles in filter cloth pores;

- Disposable filter bags: Replace immediately when saturated to avoid clogging and reduced filtration efficiency.

2. Environmental Treatment

- Filter Cake Disposal: Filter cakes with high heavy metal content must be treated as hazardous waste (e.g., stabilized landfilling); general industrial filter cakes can be used for brick-making, landfilling, or incineration;

- Filter Bag Recycling: Choose recyclable materials (e.g., PP, PET) and send them to professional recycling companies to reduce white pollution.

VI. Comparison with Other Filtration Methods

Filtration Method Applicable Solid Content Post-Dewatering Moisture Content Cost (¥/ton of wastewater) Advantages Dewatering Filter Bag 5–50 g/L 50–80% 5–15 Low cost, simple operation Membrane Separation ≤5 g/L 90–95% 20–50 High precision, high automation Centrifugal Separation 10–100 g/L 60–85% 10–20 High efficiency, small footprint Selection Advice: Prioritize dewatering filter bags for medium-to-high solid content wastewater (>10 g/L), especially in cost-sensitive or mobile operation scenarios (e.g., emergency drainage, temporary construction wastewater treatment). For further optimization, provide parameters such as sewage composition and treatment volume to customize filter bag specifications and processes. - Materials:

-

bag filters for water treatment

Bag filters are commonly used filtration devices in the water treatment field. They intercept suspended solids, colloids, particulate impurities, etc., in water through built-in filter bags, featuring simple structure, high filtration efficiency, and convenient maintenance. Below is key information and application highlights:I. Core Components and Working Principle

1. Main Structure

- Filter Housing: Mostly made of stainless steel (e.g., 304/316L) or engineering plastics, pressure-resistant and corrosion-resistant, with inlet, outlet, and filter bag chamber.

- Filter Bag: Constructed from synthetic fibers like polypropylene (PP) or polyester (PET), with precision ranging from 1–500 microns, fixed inside the filter via a top ring.

- Support Basket: Secures the filter bag to prevent deformation during filtration and guides uniform water flow through the filter media.

2. Working Principle

- Water to be treated flows into the filter through the inlet. As it passes through the filter bag, impurities are trapped inside the bag, while clean water exits through the outlet via filter bag pores.

- When the filter bag is saturated with contaminants (judged by inlet-outlet pressure difference, e.g., >0.1MPa), the bag needs replacement without disassembling the entire system.

II. Main Types and Characteristics

1. Classification by Housing Type

Type Characteristics Application Scenarios Single-bag filter Contains only 1 filter bag, compact structure, small flow rate (5–50 m³/h), low cost. Small systems, laboratories, household water purification Multi-bag filter Can install 2–24 filter bags in parallel, large flow rate (up to 500 m³/h), requires manifold design. Industrial water treatment, municipal water supply (large systems) Top-inlet/side-inlet Different inlet positions; top-inlet ensures more uniform water flow, while side-inlet suits space-constrained scenarios. Selected based on installation space 2. Classification by Pressure Rating

- Low-pressure type: ≤0.3MPa, suitable for normal or low-pressure scenarios (e.g., municipal tap water filtration).

- Medium-high pressure type: 0.6–1.6MPa, ideal for high-pressure systems like industrial circulating water or RO pretreatment.

III. Advantages and Limitations

Advantages

- Flexible filtration precision: Can meet various needs from coarse to fine filtration by replacing filter bags of different precisions (1–500 microns).

- High dirt-holding capacity: Deep filter bag structure retains more impurities, extending replacement cycles (30–50% higher dirt capacity than cartridge filters).

- Low maintenance cost: Filter bags can be replaced without professional tools, with low individual bag cost (¥10–200), minimizing downtime.

- High compatibility: Suitable for various water qualities (acidic/alkaline liquids, oily wastewater, high-temperature water) via material selection for bags and housings.

Limitations

- Higher pressure loss: Deep filtration structure causes greater water flow resistance than precise filtration methods like membrane filtration.

- Low automation level: Requires manual monitoring of pressure difference or regular bag replacement, unsuitable for unmanned scenarios (can be improved with automatic pressure alarms).

IV. Typical Application Scenarios

1. Industrial Water Treatment

- Circulating cooling water filtration: 截留 algae, sediment, rust, etc., to prevent heat exchanger blockage and extend equipment life.

- Chemical wastewater pretreatment: Removes suspended solids and colloids for subsequent biochemical or membrane treatment.

- Metalworking fluid filtration: Filters metal chips and sludge from cutting fluids for recycling.

2. Municipal and Civil Applications

- Waterworks pretreatment: Further removes fine particles after sedimentation to improve water clarity.

- Sewage plant deep filtration: Serves as a post-secondary clarifier unit to reduce effluent SS (suspended solids) concentration for compliance.

- Commercial/household water purification: Used in pool filtration, direct drinking water pretreatment (with activated carbon filter bags), etc.

3. Special Industry Applications

- Food and beverage industry: Filters impurities from syrups and alcoholic beverages to meet hygiene standards (requires FDA-certified food-grade filter bags).

- Pharmaceutical and electronics industry: Prepares high-purity water by intercepting particulate contaminants for reverse osmosis (RO) or EDI systems.

V. Selection and Maintenance Tips

1. Key Selection Parameters

- Flow rate and number of filter bags: Choose single or multi-bag filters based on system flow. A single No. 2 filter bag (810mm length) handles ~30 m³/h at 50-micron precision.

- Material compatibility:Precision selection: Based on impurity particle size (e.g., ≤5 microns for RO pretreatment, 50–100 microns for coarse filtration).

- Acidic liquids: PP filter bag + stainless steel housing;

- Oily wastewater: PET filter bag + anti-corrosion coated housing;

- High-temperature liquids (>80℃): high-temperature-resistant PET filter bag.

2. Maintenance Recommendations

- Replacement cycle:

- Normal water quality: Replace every 1–3 months (pressure difference-dependent);

- High-turbidity water: Inspect weekly and replace immediately when pressure difference reaches 0.1MPa.

- Operation notes:Environmental treatment: Prioritize degradable filter bags or centralized recycling for disposable bags to reduce pollution.

- Relieve pressure before replacing bags to avoid high-pressure water impact;

- Ensure the bag’s sealing ring tightly fits the filter to prevent bypass flow.

-

How to select water filter bags suitable for specific water treatment needs?

Choosing the right water filter bags for specific water treatment requirements requires comprehensive consideration of water quality characteristics, treatment objectives, system parameters, and application scenarios. Below is a detailed selection process and key considerations:I. Clarify water quality and treatment objectives

1. Analyze water source impurity characteristics

- Particle types: Suspended solids (e.g., sediment, rust), colloids (e.g., clay, microorganisms), oils, or specific pollutants (e.g., metal ions, organic matter).

- Particle size: Determine the main impurity particle size range through water quality testing (e.g., coarse particles >50 microns, fine particles <10 microns).

- Chemical properties: Liquid acidity/alkalinity (pH value), corrosiveness (e.g., chloride ions, strong oxidizers), and temperature (normal or high-temperature environments).

2. Define filtration goals

- Precision requirements: Target filtration accuracy (e.g., drinking water ≤5 microns, industrial circulating water up to 50 microns).

- Treatment volume: Water flow rate per unit time (e.g., 10 m³/h, 100 m³/h), affecting filter bag size and quantity.

- Impurity interception capacity: Concentration of contaminants to be intercepted (high-turbidity water sources require high dirt-holding capacity filter bags).

II. Core selection parameters

1. Filtration precision (critical parameter)

- Precision range: Common filter bag precisions range from 1–500 microns, selected based on impurity particle size.Note: Excessively high precision may cause rapid clogging; balance filtration efficiency with flow rate.

- Examples:

- Swimming pool water filtration: 20–50 microns (removes hair, sediment).

- Pre-treatment for electronic-grade ultrapure water: 1–5 microns (intercepts tiny particles).

- Chemical wastewater oil removal: 10–25 microns (paired with demulsification processes).

- Examples:

2. Material compatibility

- Common materials and applications:

Material Corrosion resistance Temperature resistance Typical applications Polypropylene (PP) Resistant to acids, alkalis, salt solutions ≤80℃ Industrial wastewater, municipal sewage, food processing Polyester (PET) Resistant to oil and general solvents ≤120℃ Lubricating oil filtration, oily wastewater treatment Nylon (PA) Resistant to strong alkalis, wear-resistant ≤90℃ High-turbidity water sources, metalworking fluid filtration - Selection principles:

- Choose PP material for acidic liquids and PA or PET for alkaline liquids.

- Select PET or special high-temperature-resistant fibers for high-temperature environments (e.g., boiler water).

3. Filter bag size and structure

- Specification categories:

- No. 1 bag: Diameter 110mm, length 380mm, flow rate ~5–15 m³/h (common in small systems).

- No. 2 bag: Diameter 180mm, length 810mm, flow rate ~20–50 m³/h (mainstream for medium-to-large systems).

- Others: No. 3 bags, No. 4 bags, or non-standard custom sizes.

- Structural design:

- Monofilament filter cloth: Smooth surface, easy to clean, suitable for intercepting large particles (coarse filtration).

- Multifilament/needle-punched filter cloth: Deep filtration, high dirt-holding capacity, suitable for fine particle filtration.

- Reinforced ring design: Stainless steel or plastic rings at the top to prevent bag mouth tearing and improve pressure resistance.

4. Pressure resistance and flow matching

- System pressure: Filter bags must withstand ≥ system operating pressure (typically 0.1–0.6MPa); use thickened materials or metal frame supports for high-pressure scenarios.

- Flow calculation:

- A single No. 2 bag at 50-micron precision has a flow rate of ~30 m³/h; for a 100 m³/h system, parallel 4 bags (with redundancy).

III. Other key factors

1. Dirt-holding capacity and replacement cycle

- Dirt-holding capacity: Total amount of impurities a filter bag can retain (unit: g/bag); high capacity reduces replacement frequency.

- Estimation method:

- For known suspended solids concentration (e.g., 500 mg/L) and total treatment volume (e.g., 1000 m³), total impurity weight = 500 mg/L × 1000 m³ = 500 kg.

- If a single filter bag holds 5 kg, it needs to be replaced 100 times per cycle, or increase the number of filter bags to reduce frequency.

2. Environmental protection and cost

- Disposable vs. washable:Material recyclability: Prioritize recyclable PP/PET materials to reduce plastic pollution.

- Disposable filter bags: Low cost (~¥10–50/bag), suitable for complex impurities or non-washable scenarios.

- Washable filter bags: Higher cost (~¥200–500/bag) but reusable, ideal for high-value liquids or strict environmental requirements.

3. Compatibility with supporting equipment

- Filter type: Must match filter bag size (e.g., No. 1 bag for small filters, No. 2 bag for standard filters).

- Sealing method: O-ring or flange sealing to ensure no leakage.

IV. Selection process example

Scenario: A food factory needs to filter production water containing sediment (particle size 20–100 microns), with a flow rate of 50 m³/h and normal-temperature neutral water.- Precision selection: Intercept particles >20 microns, choose 25-micron precision filter bags.

- Material selection: Neutral water, choose economical and durable PP material.

- Size selection: Single No. 2 bag flow rate 30 m³/h, require 2 bags in parallel (total flow 60 m³/h to cover 50 m³/h demand).

- Structure selection: Needle-punched filter cloth (deep filtration, high dirt-holding capacity) with stainless steel reinforcing rings.

- Replacement cycle: Estimated daily treatment volume 400 m³, inlet suspended solids concentration 200 mg/L, daily impurity total 80 kg; single bag dirt-holding capacity 5 kg, requires daily replacement of 2 bags (or replace every 2 days with spare bags).

V. Notes

- Testing and verification: For high-requirement scenarios (e.g., pharmaceuticals, electronics), test with sample filter bags first to confirm filtration efficiency and service life.

- Supplier qualification: Choose ISO-certified manufacturers to ensure filter bags meet hygiene standards (e.g., food-grade requires FDA certification).

- Emergency plans: Stock spare filter bags to avoid system downtime; regularly inspect for damage (replace immediately if pressure drop surges).

-

Water filter bag,Do water filter bags work?

A water filter bag is a filtration component used in the water treatment field, primarily designed to intercept suspended solids, colloids, particulate impurities, etc., in water to purify the water quality or meet specific process requirements. Its materials are typically corrosion-resistant and wear-resistant synthetic fibers such as polypropylene (PP) and polyester (PET), which are made into filter fabrics of different precisions through needle punching, weaving, or other processes, and then sewn into a bag-like structure.Main Features

- Diverse Filtration Precisions

- The precision range typically spans 1–500 microns. Filter bags with different pore sizes (e.g., 10 microns, 50 microns) can be selected according to water quality requirements to meet various needs such as coarse filtration and fine filtration.

- High Interception Efficiency

- The deep filtration structure effectively captures impurities of different particle sizes, with a large dirt-holding capacity and long service life.

- Chemical Corrosion Resistance

- The materials are resistant to acids, alkalis, and most chemical reagents, suitable for multiple scenarios such as industrial wastewater, municipal sewage, and food processing water.

- Convenient Replacement

- The bag-type structure is easy to install and replace without professional tools, reducing maintenance costs.

Application Scenarios

- Industrial Water Treatment: For example, filtration of circulating cooling water, pretreatment of chemical wastewater, and filtration of metalworking fluids to remove suspended solids and mechanical impurities.

- Municipal Water Supply/Sewage Treatment: Used for pretreatment in waterworks and secondary filtration in sewage plants to improve water clarity.

- Food and Beverage Industry: Filters production water, syrups, alcoholic beverages, etc., to ensure products meet hygiene standards.

- Pharmaceutical and Electronics Industry: Used for pretreatment of high-purity process water to intercept particulate contaminants and meet clean production requirements.

Selection Considerations

- Filtration Precision: Choose appropriate precision based on the particle size of impurities in the water source and treatment objectives (e.g., 50 microns for swimming pool water filtration, 1 micron for electronic-grade water).

- Material Compatibility: Ensure that the filter bag material is chemically compatible with the liquid to be treated (e.g., polypropylene for acidic liquids).

- Flow Rate and Pressure: Select filter bag sizes (e.g., No. 1 bag, No. 2 bag, etc.) according to the system flow rate, and ensure pressure resistance meets working conditions.

- Support Structure: Needs to be used with a bag filter; pay attention to the matching of the filter’s diameter, sealing method, and filter bag.

- Environmental Requirements: Prioritize recyclable materials or filter bags that meet environmental standards to reduce secondary pollution.

- Diverse Filtration Precisions

-

ACCU-PULSE DMF-Z-1-40S Right-angle electromagnetic pulse valve

A right-angle electromagnetic pulse valve (commonly referred to as a right-angle type electromagnetic pulse valve) is a structural variant of electromagnetic pulse valves. Its most notable feature is that the air inlet and outlet are distributed at a right angle (90 degrees), making it widely used in pneumatic control systems requiring high flow rates and efficient blowing, particularly in scenarios such as dust removal equipment (e.g., bag dust collectors) and pneumatic conveying systems.Key Features

-

Right-angle Structure

- The vertical design of the inlet and outlet allows for more direct air flow direction change, reducing air resistance and suitable for working conditions requiring rapid blowing and high flow rates.

- Generates a strong impact force during blowing, effectively removing dust from the surface of filter bags or pushing materials.

-

Electromagnetic Control

- Controls the opening and closing of the valve core through the energization or de-energization of an electromagnetic coil, achieving instantaneous release of pulsed air flow (blowing time typically ranges from tens of milliseconds to several seconds).

- Features fast response and precise control, enabling automated operation through an electronic control system.

-

High Reliability

- Compact structure and good sealing performance make it suitable for continuous industrial operations.

- The valve body is mostly made of metal materials (such as aluminum alloy or stainless steel), offering wear resistance and corrosion resistance.

Application Scenarios

- Dust Removal Systems: In bag dust collectors, right-angle electromagnetic pulse valves periodically blow compressed air to remove dust from filter bags and restore their air permeability.

- Pneumatic Conveying: Used to control pulsed conveying of materials in pipelines, especially suitable for efficient transportation of granular or powdery materials.

- Chemical/Environmental Protection Equipment: Serves as a key actuator in automated equipment requiring rapid air flow start-stop.

Selection Considerations

- Interface Dimensions: Choose appropriate inlet and outlet pipe diameters (e.g., DN15, DN25) according to the system pipeline specifications.

- Operating Pressure: Confirm the applicable compressed air pressure range (e.g., 0.4–0.7MPa).

- Blowing Volume: Select a suitable valve capacity (blowing air volume) based on the required dust removal or conveying capacity.

- Power Supply Type: Common options include DC24V or AC220V, which need to match the control system.

- Environmental Adaptability: Consider working conditions such as temperature, humidity, and dust concentration, and select anti-corrosion and dust-proof valve bodies.

-

-

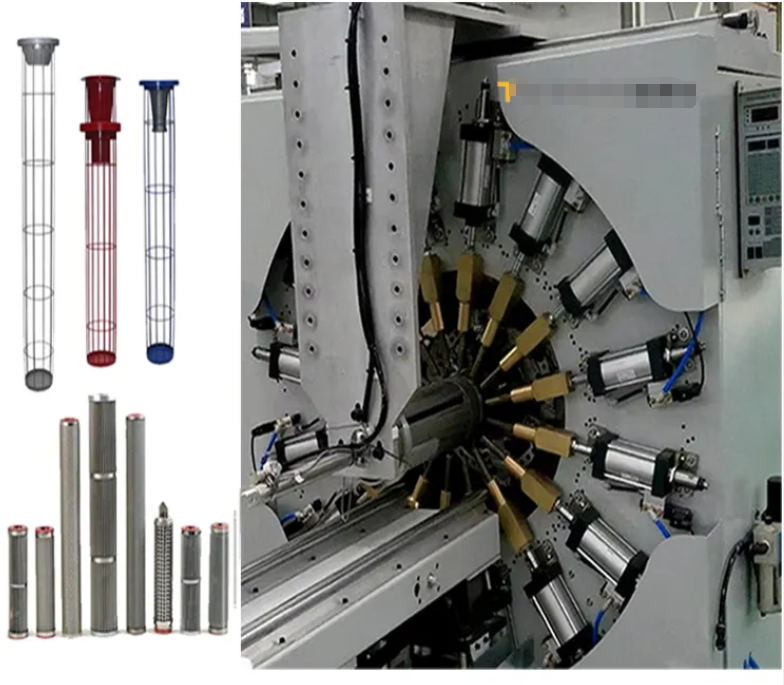

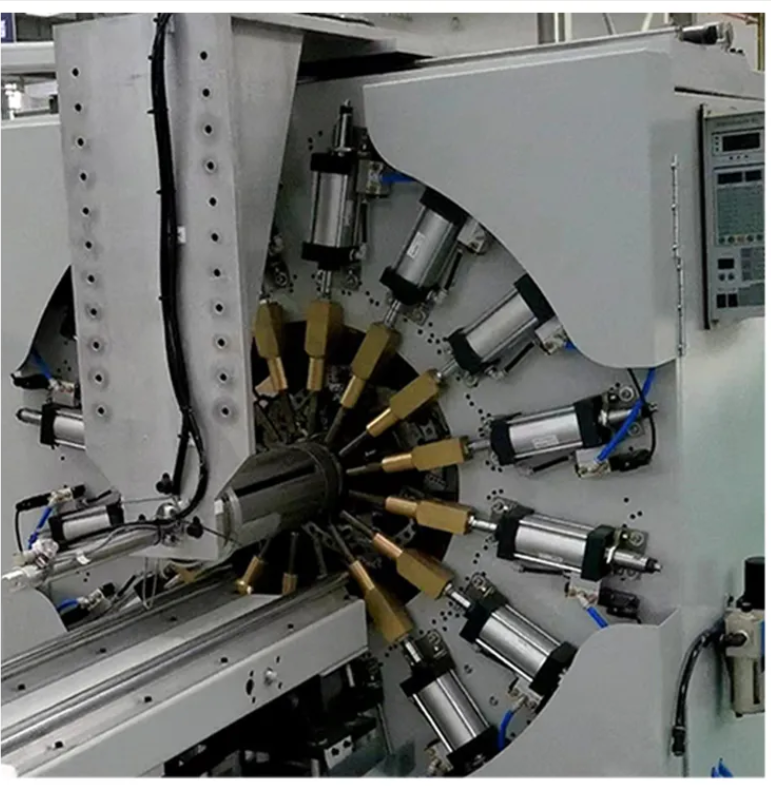

Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line Metal Processing: An Ideal Solution for Multiple Industries

The Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line, as an advanced equipment in the field of metal processing, has a wide range of applications, bringing efficient and high-quality production solutions to multiple industries.

In the environmental protection equipment manufacturing industry, filter cartridge dust collectors are key devices for air purification and dust treatment, and the filter cage dust collector frame is a core component. The Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line can quickly and accurately weld the filter cage dust collector frame, ensuring the quality and stability of the frame. A high-quality frame can not only extend the service life of the filter cartridge dust collector but also guarantee its dust removal effect during operation, providing enterprises with reliable environmental protection equipment and helping them meet increasingly stringent environmental requirements.In the industrial equipment manufacturing field, many large-scale mechanical equipment require metal frame structures. This automatic line can flexibly adjust welding parameters and processes according to different design requirements, producing metal frames of various specifications and shapes. Whether it is the sturdy frame of heavy machinery and equipment or the lightweight frame of precision instruments, efficient and precise welding production can be achieved through this automatic line, providing reliable component supply for industrial equipment manufacturing enterprises and enhancing the overall quality and performance of products.For the steel structure construction industry, the Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line also has important application value. During the construction of steel structure buildings, a large number of metal components need to be welded. This automatic line can quickly and efficiently complete these welding tasks while ensuring the consistency and stability of welding quality. The steel structure components produced by this automatic line can better meet the requirements of architectural design, improve the structural strength and safety of buildings, shorten the construction period, and reduce construction costs.The Filter Cage Dust Collector Frame Multi-Head Spot Welding Automatic Line, with its excellent performance in metal processing and wide applicability, has become an ideal solution for production and manufacturing in multiple industries. It not only improves the production efficiency and product quality of enterprises but also provides strong technical support for the development of various industries, promoting the progress and development of related industries. -

The ACCU-PULSE DMF-Z-25 pulse valve

The DMF-Z-25 pulse valve is a right-angle electromagnetic pulse valve commonly used in the cleaning and injection systems of pulse-jet bag dust collectors, serving as a “switch” for compressed air. The detailed introduction is as follows:

The ACCU-PULSE DMF-Z-25 pulse valve Working Principle

The DMF-Z-25 pulse valve is a pilot-type solenoid valve. When energized, the electromagnetic force drives the pilot valve to open, rapidly reducing the pressure in the upper cavity of the main valve. A pressure difference is formed between the upper and lower cavities of the main valve, and the medium pressure pushes the closing member of the main valve upward, opening the valve and allowing compressed air to spray out through the valve outlet. When power is cut off, the spring force closes the pilot valve, and the inlet medium pressure quickly enters the upper cavity of the main valve through the pilot hole, forming a pressure difference in the upper cavity to close the main valve and stop the pulse valve from exhausting air.The ACCU-PULSE DMF-Z-25 pulse valve Technical Parameters

- Connection Thread: ZG1″

- Nominal Diameter: 25mm

- Working Pressure: 0.3–0.8 MPa

- Applicable Medium: Clean air

- Working Voltage: AC24V, AC110V, AC220V, DC24V, etc.

- Ambient Temperature: -10–55°C

- Diaphragm Service Life: Over 1 million injections

The ACCU-PULSE DMF-Z-25 pulse valve Product Features

- Right-Angle Structure: The 90° angle between the inlet and outlet is suitable for the installation and connection of air bags and dust collector injection pipes. The smooth air flow can provide the required cleaning air pulses.

- Low-Resistance Design: The low gas resistance in the pipe allows it to be used with low-pressure air sources. Compared with high-pressure valves, it can reduce energy consumption and extend the service life of the diaphragm.

- Reliable Performance: It has good sealing performance and fast response capability, ensuring stable operation during frequent pulse injection and guaranteeing the dust cleaning effect of the dust collector.

The ACCU-PULSE DMF-Z-25 pulse valve Application Fields

It is mainly applied in pulse-jet bag dust collectors in industries such as cement, power, chemical, metallurgy, and steel. By cooperating with pulse injection control instruments, it performs row-by-row (chamber-by-chamber) injection cleaning on filter bags, maintaining the resistance of the dust collector within a set range to ensure the dust collector’s processing capacity and dust collection efficiency. -

DMF-Z-2-20 ACCU-PULSE valve with nut

DMF-Z-2-20 pulse valve with nut is a right-angle electromagnetic pulse valve commonly used in pulse-jet bag dust collectors as a “switch” for compressed air. The detailed introduction is as follows:

DMF-Z-2-20 ACCU-PULSE Working Principle

The diaphragm divides the electromagnetic pulse valve into front and rear air chambers. When compressed air is connected, it enters the rear air chamber through the orifice, and the pressure in the rear air chamber presses the diaphragm assembly tightly against the valve’s outlet, keeping the electromagnetic pulse valve in the “closed” state. When the pulse injection control instrument sends an electrical signal, the armature of the electromagnetic pulse valve moves backward, opening the rear air chamber and rapidly releasing pressure. The diaphragm assembly moves backward, allowing compressed air to spray out through the valve outlet, and the pulse valve enters the “open” state. When the electrical signal from the pulse injection control instrument disappears, the armature of the electromagnetic pulse valve resets, the exhaust port of the rear air chamber closes, the pressure in the rear air chamber rises, and the diaphragm assembly moves close to the valve’s outlet, re-closing the pulse valve.DMF-Z-2-20 ACCU-PULSE Technical Parameters

- Connection Thread: G3/4″

- Working Pressure: 0.2–0.7 MPa

- Applicable Medium: Clean air

- Working Voltage: DC12V, DC24V, AC110V, AC220V, etc.

- Diaphragm Service Life: Over 1 million injections

Product Features

- Large Air Chamber Volume: The diaphragm lifts to a large height, delivering a high injection volume and providing sufficient dust-cleaning power for the dust collector.

- Flexible Installation: It allows for a larger installation distance, making it easy to operate with tools during installation and offering suitable installation methods. Meanwhile, the larger spacing between filter bags prevents bottom collisions and friction of long bags.

- Superior Diaphragm Performance: The diaphragm is thin, tough, and highly elastic, enabling a large injection distance for each pulse. Even 8-meter-long dust bags can be injected to the bottom.

DMF-Z-2-20 ACCU-PULSE Application Field

It is mainly used in the dust-cleaning injection system of bag-type dust collectors. By cooperating with a pulse injection control instrument, it performs row-by-row (chamber-by-chamber) injection cleaning on filter bags, maintaining the dust collector’s resistance within a set range to ensure dust removal capacity and efficiency.