Products

-

ACCU-PULSE DMF-Z-20 pulse valve

DMF-Z-20 pulse valve is a right-angle electromagnetic pulse valve commonly used in pulse-jet bag dust collectors as a “switch” for compressed air. The detailed introduction is as follows:Working Principle

The diaphragm divides the electromagnetic pulse valve into front and rear air chambers. When compressed air is connected, it enters the rear air chamber through the orifice, and the pressure in the rear air chamber presses the diaphragm assembly tightly against the valve’s outlet, keeping the electromagnetic pulse valve in the “closed” state. When the pulse injection control instrument sends an electrical signal, the armature of the electromagnetic pulse valve moves backward, opening the rear air chamber and rapidly releasing pressure. The diaphragm assembly moves backward, allowing compressed air to spray out through the valve outlet, and the pulse valve enters the “open” state. When the electrical signal from the pulse injection control instrument disappears, the armature of the electromagnetic pulse valve resets, the exhaust port of the rear air chamber closes, the pressure in the rear air chamber rises, and the diaphragm assembly moves close to the valve’s outlet, re-closing the pulse valve.Technical Parameters

It is mainly used in the dust-cleaning injection system of bag-type dust collectors. By cooperating with a pulse injection control instrument, it performs row-by-row (chamber-by-chamber) injection cleaning on filter bags, maintaining the dust collector’s resistance within a set range to ensure dust removal capacity and efficiency. -

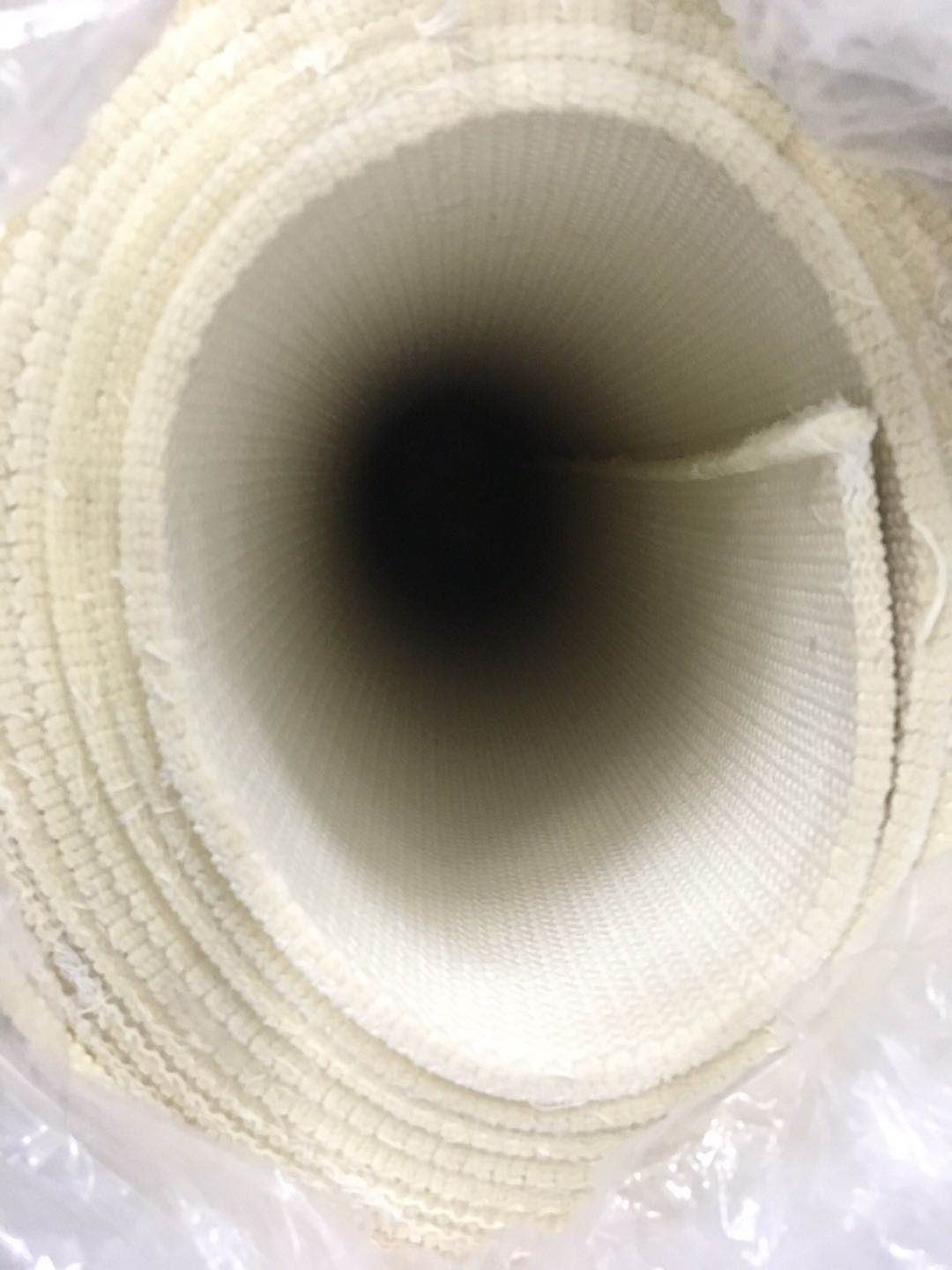

Factory-customized air filter elements

This is a cylindrical air filter element. An air filter element is an important component for filtering impurities in the air and is widely used in the intake systems of automotive engines, the air – intake devices of industrial mechanical equipment, air purifiers, and other equipment. Its principle is to utilize the filtering properties of the filter – element material to intercept pollutants such as dust, particles, and pollen in the air, providing clean air for the equipment.

This prevents these impurities from entering the interior of the equipment, avoiding component wear and blockages, and ensuring the normal operation and service life of the equipment. The corrugated structure design of the filter element in the picture increases the filtering area and can improve the filtering efficiency and dust – holding capacity.

-

Electromagnetic Pulse Valves: Opening a New Era of Intelligent Industrial Cleaning

With the advent of the intelligent industrial era, electromagnetic pulse valves are also actively integrating into the intelligent wave and becoming a key part of realizing intelligent industrial cleaning.Intelligent electromagnetic pulse valves are equipped with advanced sensors and intelligent control systems. These sensors can real – time monitor key parameters such as the resistance of the filter bag, dust concentration, and the operating status of the equipment. Take the large – scale dust removal system in a chemical enterprise as an example. The sensors transmit the collected data to the intelligent control system in real – time. The system analyzes and processes these data to accurately judge the ash – cleaning requirements of the filter bag. When the resistance of the filter bag reaches the set threshold, the intelligent control system automatically issues an instruction to control the electromagnetic pulse valve for ash – cleaning operation. Moreover, the system can automatically adjust the injection time, injection interval, and injection pressure of the electromagnetic pulse valve according to the actual situation to ensure the ash – cleaning effect while minimizing energy consumption.The intelligence of electromagnetic pulse valves is also reflected in remote monitoring and fault diagnosis functions. With the help of the Internet of Things technology, enterprise managers can remotely monitor the operating status of electromagnetic pulse valves at any time through terminal devices such as mobile phones and computers. Once a fault occurs in the equipment, the intelligent system can quickly issue an alarm and accurately locate the fault point through data analysis. For example, in the dust removal equipment of the mining industry, if a fault such as valve core jamming occurs in the electromagnetic pulse valve, the intelligent system will immediately notify the maintenance personnel and provide detailed fault information, greatly shortening the equipment maintenance time and improving production efficiency.The intelligent transformation of electromagnetic pulse valves has brought higher efficiency, lower costs, and more reliable operation guarantees for industrial cleaning. It has opened a new era of intelligent industrial cleaning, enabling industrial production to continuously move forward on the path of environmental protection and high – efficiency, laying a solid foundation for realizing a sustainable industrial future. -

Electromagnetic Pulse Valves: Key Equipment for Promoting the Upgrading of the Environmental Protection Industry

The environmental protection industry occupies an increasingly important position in today’s social development. As a key component of environmental protection equipment, electromagnetic pulse valves are promoting the technological upgrading and efficient development of the environmental protection industry.Picture (DMF-Z-40S Pulse Valve)

Electromagnetic pulse valves have the significant advantage of fast response speed. In some production environments with extremely strict requirements for dust emissions, such as electronic chip manufacturing workshops, electromagnetic pulse valves can respond in a very short time. Once it is detected that the dust accumulation on the surface of the filter bag reaches a certain level, the control system issues an instruction, and the electromagnetic pulse valve can quickly open and complete a pulse injection action within a few milliseconds, timely removing the dust on the filter bag and ensuring that the air quality in the workshop always meets strict standards, providing a clean environment for precision production.

The energy – saving characteristics of electromagnetic pulse valves are also remarkable. The ash – cleaning methods of traditional dust removal equipment often consume a large amount of energy. Modern electromagnetic pulse valves, through optimized design, can precisely control the injection volume and injection time of compressed air. For example, in the small – scale dust removal system used in a food processing factory, the electromagnetic pulse valve adopts intelligent control technology. It automatically adjusts the injection parameters according to the actual working conditions of the filter bag. In this way, while meeting the ash – cleaning requirements, it greatly reduces the waste of compressed air, reducing the energy consumption and operating costs of enterprises.On the path of the environmental protection industry’s continuous pursuit of green and efficient development, the importance of electromagnetic pulse valves has become more prominent. It not only improves the performance and reliability of environmental protection equipment but also provides strong support for enterprises to achieve energy conservation, emission reduction, and sustainable development. With the increasingly strict environmental protection standards, electromagnetic pulse valves will have a broader development space and continue to contribute to the upgrading of the environmental protection industry. -

Electromagnetic Pulse Valves: The Core Power of Industrial Dust Removal Systems

In modern industrial production, dust pollution not only poses a threat to the environment but also seriously endangers the normal operation of production equipment and the health of workers. As a key component of industrial dust removal systems, electromagnetic pulse valves play an irreplaceable role.The working principle of electromagnetic pulse valves is based on the law of electromagnetic induction. When the electromagnetic coil of an electromagnetic pulse valve is energized, the generated electromagnetic force overcomes the spring force, lifts the valve core, opens the gas passage, and allows compressed air to spray out rapidly. When the electromagnetic coil is de-energized, the electromagnetic force disappears, and the spring force makes the valve core return to its original position, closing the gas passage and stopping the gas injection. This rapid opening and closing action can precisely control the injection time and frequency of compressed air.In the field of industrial dust removal, electromagnetic pulse valves are widely used. Take a cement plant as an example. A large amount of dust is generated during the production process. In a bag filter, the electromagnetic pulse valve emits a pulse jet at regular intervals. The compressed air is sprayed into the interior of the filter bag at high speed. The strong air flow impact causes the filter bag to expand and vibrate instantaneously, shaking off the dust attached to the surface of the filter bag, thus achieving the ash cleaning of the filter bag. In this way, not only can the air permeability of the filter bag be ensured, the high – efficiency operation of the dust collector be maintained, but also the service life of the filter bag can be extended, reducing the operating costs of enterprises.In other industrial fields such as steel plants and thermal power plants, electromagnetic pulse valves also play an important role. They ensure a clean production environment, reduce the erosion of dust on equipment, and improve the safety and stability of production. With the continuous progress of industrial technology, electromagnetic pulse valves are also constantly innovating and developing, moving towards higher performance, more energy – saving, and more intelligent directions to meet the needs of future industrial development. -

Introduction of DMK-4CSA-20 Controller

1. Overview

The DMK-4CSA-20 is a pulse injection controller, which serves as the main control device for the pulse injection cleaning system of the pulse bag dust collector. It controls the electromagnetic pulse valves by outputting signals, enabling the compressed air to cyclically inject and clean the filter bags. This maintains the resistance of the dust collector within the set range, ensuring the dust collector’s processing capacity and dust removal efficiency.2. Functional Features

- Flexible Control Modes: It adopts a programmable combined output mode, capable of achieving one-machine control for small-scale dust collectors with less than 19 output points. It can be combined into a mode of M lift valves + N pulse valves, easily realizing M + MN point switch quantity output. It can achieve both online and offline control. When M = 0, it is in the offline cleaning mode.

- Superior Output Performance: Using imported high-power contactless devices for output, it can achieve real-time output of the pulse valves, improving the hysteresis phenomenon of relay output.

- Diverse Parameter Settings: The core control uses a single-chip microcomputer, allowing the setting of key parameters, including digital display, cycle interval, pulse interval, and pulse width, etc. And it controls the cleaning process according to the “Stop/Run” signal. The output pulse width can be adjusted within the range of 0.01 – 0.99 seconds. The adjustment range of the output pulse interval is 1 – 99 seconds, and the adjustable range of the cycle interval is 0 – 99 minutes.

3. Technical Parameters

- Input Voltage: 220V AC.

- Output Voltage: 24V DC.

- Number of Output Bits: 20 bits, which can control 9 – 20 electromagnetic pulse valves.

- Dimensions: 240mm×160mm×90mm.

- Working Environment: The temperature ranges from -25℃ to 55℃, the relative humidity is less than 85%, and there is no serious corrosive gas, conductive dust, severe vibration, or impact in the surroundings.

-

PE500c1 Filter Cloth Product Introduction

1. Product Overview The PE500c1 filter cloth is a premium filtration material meticulously crafted to deliver outstanding performance in a wide array of filtration applications. Made from high-quality polyethylene (PE) with the unique characteristics of the “c1″ variant, it offers a combination of durability, efficiency, and reliability that sets it apart in the market.

2. Material Properties – **High-Quality Polyethylene Base**: The PE500c1 filter cloth is constructed from top-grade polyethylene, which provides it with excellent physical properties. This material has a high tensile strength, allowing the filter cloth to withstand the rigors of the filtration process without tearing or deforming easily. It can endure significant mechanical stress, whether it’s during the filtration operation or when handling the cloth for installation and cleaning. – **Unique “c1″ Characteristics**: The “c1″ designation indicates specific enhancements or modifications to the base PE material. These may include optimized molecular structure for improved chemical resistance, better fiber orientation for enhanced filtration efficiency, or surface treatments that contribute to its anti-clogging and easy-release properties. These unique features make the PE500c1 filter cloth more adaptable to various challenging filtration environments.

3. Key Features – **Superior Filtration Efficiency**: The PE500c1 filter cloth is designed with a precisely engineered pore structure. This allows it to effectively capture particles of different sizes, ensuring high-precision filtration. Whether it’s separating fine solids from liquids in chemical processes or removing contaminants from industrial wastewater, it can achieve excellent separation results, delivering a clear filtrate. – **Exceptional Chemical Resistance**: Thanks to its PE base and the “c1″ modifications, the filter cloth has strong resistance to a wide range of chemicals. It can withstand exposure to acids, alkalis, and many organic solvents without being damaged or deteriorating in performance. This makes it suitable for use in industries such as chemical manufacturing, where harsh chemical environments are common. – **Long Service Life**: Its robust construction and high-quality materials contribute to a long lifespan. The filter cloth can maintain its filtration performance over an extended period, reducing the need for frequent replacements. This not only saves on costs but also minimizes downtime associated with filter cloth changes, improving overall production efficiency. – **Good Cake Release and Anti-Clogging**: The surface properties of the PE500c1 filter cloth enable easy release of the filtered cake. Particles do not adhere firmly to the cloth, making it simple to remove the solids after filtration. Additionally, its design helps prevent clogging of the pores, ensuring continuous and unobstructed filtration even when dealing with viscous or sticky substances.

4. Application Areas – **Chemical Industry**: Widely used in chemical reactors for separating reaction products from solvents, purifying chemical intermediates, and filtering out impurities in chemical solutions. It can handle a variety of chemical processes with different requirements, providing reliable filtration performance. – **Mining and Mineral Processing**: In the mining industry, the PE500c1 filter cloth is employed for dewatering of mineral slurries, separating valuable minerals from waste materials, and treating mining wastewater. Its ability to withstand heavy loads and harsh environmental conditions makes it a preferred choice for these applications. – **Food and Beverage Production**: For filtering fruit juices, wines, edible oils, and other food products, the PE500c1 filter cloth meets strict hygiene standards. It ensures that the final products are free from contaminants while maintaining their taste and quality. – **Water Treatment**: In both industrial and municipal water treatment plants, it can be used for removing suspended solids, turbidity, and other impurities from water sources. It helps in producing clean water that meets the required quality standards for various applications.

5. Technical Specifications – **Filtration Precision**: [Specify the range of particle sizes it can effectively filter, e.g., 0.5 - 50 microns] – **Tensile Strength**: Longitudinal: [Provide the value in appropriate units, e.g., N/cm] Transverse: [Provide the value in appropriate units, e.g., N/cm] – **Operating Temperature Range**: [Specify the minimum and maximum temperatures, e.g., -10°C to 80°C] – **pH Resistance Range**: [Indicate the pH values it can withstand, e.g., 2 - 12]

If you have any questions or need more detailed information about the PE500c1 filter cloth, or if you have specific requirements for your filtration applications, please feel free to contact our professional team. We are committed to providing you with the best solutions and excellent after-sales support.

-

PE500/PTFE Filter Cloth Product Introduction

PE500/PTFE Filter Cloth Product Introduction

1. Product Overview The PE500/PTFE filter cloth combines the excellent properties of polyethylene (PE500) and polytetrafluoroethylene (PTFE), presenting itself as a high – performance filter material. It is engineered to meet the diverse filtration needs across multiple industries, providing efficient solid – liquid separation and ensuring long – term stable operation.

2. Material Characteristics -

**PE500**: This material endows the filter cloth with high tensile strength and good toughness, enabling it to withstand significant mechanical stress during the filtration process without easily deforming or breaking. It also exhibits good chemical resistance to a wide range of common chemicals, protecting the filter cloth from corrosion and extending its service life. –

PTFE: Known as “King of Plastics”, PTFE has outstanding chemical inertness, being resistant to almost all chemicals, including strong acids, alkalis, and organic solvents. Additionally, it has extremely low surface energy, resulting in excellent anti – sticking properties. Particles and residues are less likely to adhere to the surface of the PTFE – based filter cloth, facilitating easy cake release and reducing the frequency of cleaning.

3. Key Features – **High Filtration Efficiency**: With precisely controlled pore sizes, the PE500/PTFE filter cloth can effectively capture fine particles, achieving high – precision filtration. Whether filtering suspended solids in liquid or separating dust in gas, it can ensure the filtrate or discharged gas meets strict quality standards.

Long Service Life: Thanks to the excellent chemical and mechanical properties of its materials, the filter cloth has remarkable durability. It can maintain stable filtration performance over extended periods of continuous operation, reducing the frequency of replacement and thereby lowering overall operating costs.

**Good Chemical Stability**:

Resistant to various harsh chemical environments, it can be safely used in industries such as chemical engineering, pharmaceuticals, and electroplating, where highly corrosive substances are often present. – **Easy to Clean**: The anti – sticking property of PTFE makes cleaning a breeze. Both mechanical cleaning methods, such as backwashing and vibration, and chemical cleaning can effectively remove residues on the filter cloth, restoring its filtration performance quickly. ## 4. Application Scenarios – **Chemical Industry**: Ideal for filtering chemical reaction products, separating catalysts, and purifying chemical solvents. It can handle highly corrosive chemical media while maintaining high – quality filtration. – **Pharmaceutical Industry**: Used in the production process to filter pharmaceutical intermediates and final products, ensuring product purity and compliance with strict pharmaceutical standards. Its non – shedding and high – cleanliness characteristics are crucial in pharmaceutical manufacturing.

**Food and Beverage Industry**:

Suitable for filtering fruit juices, beverages, and edible oils. It meets food – grade safety requirements, ensuring no harmful substances are introduced during the filtration process and maintaining the taste and quality of food products. – **Mining and Metallurgy**: Helps in separating valuable minerals from ores and purifying wastewater generated during the mining and metallurgical processes. Its high – strength structure can withstand the harsh conditions of the mining environment.

5. Technical Parameters – *

*Filtration Precision**: [Specify the precise range, e.g., 0.1 - 100 microns] – **Tensile Strength**: [Provide the data, e.g., longitudinal tensile strength ≥ [X] N/cm, transverse tensile strength ≥ [Y] N/cm] – **Working Temperature**: – [X] °C to [X] °C – **pH Resistance Range**: [Specify the applicable pH range, e.g., 1 - 14]

If you have any further questions or specific requirements regarding our PE500/PTFE filter cloth, please feel free to contact us. Our professional team is ready to offer you detailed solutions and excellent after – sales service.

-

Wide Applications of Filter Bags

In the industrial field, filter bags can be seen everywhere. In the chemical industry, they are used for the filtration of various chemical raw materials and products, ensuring product quality and the smooth progress of the production process. In the food and beverage industry, from the filtration of raw materials to the filtration before filling of finished products, they ensure the safety and taste of food and beverages. In the pharmaceutical industry, which has extremely high requirements for filtration accuracy and hygiene, filter bags are used for the filtration of liquid medicines, removing impurities and microorganisms to ensure the quality and safety of drugs.

In the environmental protection field, filter bags play an important role. In sewage treatment plants, filter bags are used to filter impurities and suspended solids in sewage, laying the foundation for subsequent treatment processes. In industrial waste gas treatment, dust – removal filter bags can effectively reduce dust emissions, reduce pollution to the atmospheric environment, and help achieve environmental protection goals.In daily life, filter bags also quietly serve us. The water purifiers at home may use filter bags to filter impurities in water, allowing us to drink cleaner water. The pour – over coffee filter bags used by coffee lovers can filter out coffee grounds, bringing a pure coffee taste. Even in the kitchen, some filter bags for making soup can filter out the residue in the soup, making the soup more delicious.Although filter bags seem inconspicuous, they play an indispensable role in various fields. With the continuous progress of science and technology and the increasing requirements for filtration, the performance and quality of filter bags are also constantly improving. In the future, they will continue to serve as key guardians in the filtration world, escorting our lives and production. -

The Ingenious Working Principle of Filter Bags

he working principle of filter bags is mainly based on functions such as screening, interception, and adsorption. Taking liquid filter bags as an example, when the liquid flows from the inside to the outside of the filter bag, particles larger than the pore size of the filter bag will be directly intercepted inside the bag, which is the screening function. For some smaller particles, although they can pass through the pore size of the filter bag, they will be retained inside the filter bag due to the interception of the filter bag fibers and the mutual collision of particles, which belongs to the interception function. In addition, the material of the filter bag itself may have certain adsorption properties for some substances, which can adsorb some tiny impurities and pollutants, further improving the filtration effect.

In the entire filtration system, filter bags work together with filter containers, support baskets, etc. The liquid or gas to be filtered is injected from the top of the filter bag supported by the support basket, making the fluid evenly distributed on the entire surface of the filter bag, avoiding adverse factors such as turbulence. This design can make full use of the filtration area of the filter bag and improve the filtration efficiency. Moreover, the filtered particles are intercepted inside the bag, and the filtered fluid will not be contaminated when replacing the filter bag. Some filter bags are also designed with handles for quick and convenient replacement of filter bags. -

Filter Bags: The Key Guardians in the Filtration World

In the world we live in, filtration is everywhere, from the water and coffee we drink daily to various liquids and gases in industrial production. Among numerous filtration devices, filter bags have become a crucial part of the filtration process due to their unique performance and wide applications.I. A Wide Variety of Filter Bags

Filter bags are made of diverse materials, enabling them to meet various filtration requirements. Common materials include polyester, polypropylene, nylon, glass fiber, FMS (Fluoride Modified Synthetic Fiber), etc.Polyester filter bags have good chemical stability and certain strength and are widely used in general liquid filtration, such as in industrial wastewater treatment and chemical liquid filtration. Polypropylene filter bags have good resistance to acids and alkalis and are often used in some liquid filtration scenarios with strong corrosiveness, such as the filtration of electroplating solutions and chemica raw material liquids. Nylon filter bags have precise pore sizes and can achieve high – precision filtration. They play an important role in the food and beverage industry, such as in the filtration of wine and fruit juice, ensuring the purity of products. Glass fiber filter bags have excellent high – temperature resistance and can be used for the filtration of high – temperature gases, for example, in the high – temperature flue gas dust removal in steel plants and cement plants. FMS filter bags are not only resistant to high temperatures but also highly corrosion – resistant, suitable for some harsh industrial environments.Iln terms of structure and use, filter bags can be divided into liquid filter bags, dust – removal filter bags, air – purification filter bags, etc. Liquid filter bags have different filtration accuracies ranging from 0.5 microns to 300 microns, which can meet various needs from high – precision liquid filtration in the electronics industry to general industrial liquid rough filtration. Dust – removal filter bags are mainly applied in the industrial dust – removal field. In places like cement plants and steel plants, they can effectively capture dust, reduce dust pollution to the environment, and ensure a clean production environment. Air – purification filter bags are commonly found in air – conditioning systems and air purifiers, filtering dust, pollen, bacteria, and other pollutants in the air to provide people with fresh and healthy air. -

Product Advantages of Water Filter Bags: Superior Performance Making It the Industry’s First Choice

Water filter bags hold a pivotal position in the water treatment market and are highly favored by various industries. This is mainly due to a series of remarkable and unique product advantages they possess.High – efficiency Filtration Performance for Precise Water Purification

One of the core advantages of water filter bags is their outstanding filtration performance. According to different filtration requirements, it can accurately match filter cloths of various pore sizes, efficiently intercepting impurities ranging from large particles in millimeters to fine impurities in microns or even nanometers. For example, in industrial wastewater treatment, the wastewater from some metal processing industries often contains a large number of large – sized metal debris, sediment and other impurities, as well as micron – sized colloidal particles and bacteria and microorganisms generated by chemical reactions. By carefully selecting the appropriate pore – sized filter cloth, water filter bags can separate these impurities of different particle sizes one by one, making the treated.