Pulse Valve

-

DMF – Z-2 – 20 Valve: The High – Efficiency Dust Cleaning Tool in the Industrial Field

In numerous aspects of industrial production, dust treatment has always been a crucial issue. A large amount of dust not only affects the production environment and endangers the health of workers but may also cause damage to equipment and reduce production efficiency. To solve this problem, various dust removal equipment has emerged, and among these devices, the DMF – Z-2 - 20 valve plays an extremely vital role.

The DMF - Z-2 - 20 valve, whose full name is the right – angle electromagnetic pulse valve, is the core component of the pulse jet dust collector’s cleaning and blowing system, much like the “heart” of the entire dust removal system. As a key type of pulse jet valve, it mainly functions as a “switch” for compressed air. Under the precise control of the output signal from the pulse jet control instrument, it conducts blowing and dust cleaning on the filter bags row by row (or chamber by chamber). Just like a well – trained conductor, it accurately controls the dust cleaning rhythm, ensuring that the resistance of the dust collector remains within the set reasonable range. This effectively guarantees the high – efficiency processing capacity and excellent dust collection efficiency of the dust collector, highlighting the importance of electromagnetic pulse valves in industrial dust removal.In terms of structural design, the DMF - Z-2 - 20 valve demonstrates unique ingenuity. The included angle between its inlet and outlet is cleverly designed to be 90°, and this right – angle structure is highly suitable for the installation and connection of the air bag and the dust collector’s blowing pipe. It ensures unobstructed air flow, providing a strong and stable air pulse for the dust cleaning process, similar to a wide and smooth highway that enables compressed air to reach the areas requiring dust cleaning quickly and efficiently. This optimized design makes the DMF - Z-2 - 20 valve a standout among pulse jet valves in terms of practicality and performance.Regarding the working principle, the DMF - Z-2 - 20 valve embodies sophisticated mechanical and electromagnetic principles. The diaphragm, acting like a sensitive “goalkeeper,” clearly divides the electromagnetic pulse valve into front and rear air chambers. When compressed air is connected, it slowly enters the rear air chamber through the throttle hole, much like a silent visitor. At this time, the pressure in the rear air chamber gradually increases, similar to an inflating balloon, pressing the diaphragm assembly tightly against the valve’s outlet, keeping the electromagnetic pulse valve in a stable “closed” state. However, when the pulse jet control instrument sends out an electrical signal, a dramatic change occurs. This electrical signal acts like an urgent command, causing the armature of the electromagnetic pulse valve to move backward rapidly, instantly opening the vent hole of the rear air chamber. The air in the rear air chamber loses pressure rapidly, like a burst dam. Under the strong effect of the pressure difference, the diaphragm assembly moves backward quickly, opening up a passage for the compressed air, allowing it to be ejected with a powerful blowing force through the valve outlet. At this moment, the electromagnetic pulse valve enters the “open” state for efficient dust cleaning of the filter bags. When the electrical signal from the pulse jet control instrument disappears, the armature of the electromagnetic pulse valve returns to its original position, the vent hole of the rear air chamber closes, the pressure in the rear air chamber gradually increases again, and the diaphragm assembly adheres to the valve’s outlet once more, bringing the electromagnetic pulse valve back to the “closed” state, awaiting the next dust cleaning command. This complex yet precise working mechanism is a key feature of high – performance electromagnetic pulse valves.In terms of material selection, the DMF - Z-2 - 20 valve also demonstrates a pursuit of high quality. Its valve body is usually made of high – quality aluminum alloy materials, such as ADC12 aluminum alloy. This material offers many advantages, including light weight, high strength, and corrosion resistance. It not only reduces the overall weight of the valve, facilitating installation and maintenance but also maintains excellent performance in complex industrial environments, extending the valve’s service life. The diaphragm, on the other hand, is mostly made of high – performance materials like nitrile butadiene rubber (NBR). These materials have excellent flexibility and wear resistance, ensuring good sealing performance during frequent opening and closing operations and guaranteeing the stable operation of the valve. These material choices contribute to the DMF - Z-2 – 20 valve’s reliability and durability as a top – notch pulse jet valve.In practical applications, the DMF - Z-2 – 20 valve can be widely found in various industries. In the cement production industry, it acts like a loyal guardian, safeguarding the cleanliness of the production environment. During cement production, a large amount of dust is generated. The DMF - Z-2 – 20 valve, through precise dust cleaning control, ensures the efficient operation of the dust collector, keeping the dust concentration in the workshop within a safe range. This not only protects the health of workers but also reduces the wear and tear of dust on equipment and improves production efficiency. In the steel smelting industry, facing harsh environments with high temperatures and heavy dust, the DMF – Z – 20 valve can still operate stably. It effectively removes a large amount of dust generated during the smelting process, ensuring the normal operation of production equipment and providing strong support for the smooth progress of steel production. Additionally, in numerous industries such as mining, chemical engineering, and power generation, the DMF - Z-2 – 20 valve plays an indispensable role, becoming a reliable assistant for ensuring environmental cleanliness and stable equipment operation in industrial production. Its wide application across industries further validates the significance of electromagnetic pulse valves like the DMF - Z-2 – 20 in modern industrial operations.In conclusion, the DMF - Z-2 – 20 valve, with its unique structural design, sophisticated working principle, high – quality material selection, and extensive application areas, showcases excellent performance and strong advantages in the field of industrial dust removal. It not only helps enterprises solve the problem of dust pollution but also makes important contributions to achieving the goals of green, efficient, and sustainable industrial production, making it a well – deserved high – efficiency dust cleaning tool in the industrial field. With the continuous advancement of technology and the increasing demands of industrial production, it is believed that the DMF - Z-2 – 20 valve will continue to innovate and develop, bringing more surprises and value to the industrial field. As a prominent electromagnetic pulse valve, it will surely play an even more important role in the future of industrial dust removal and related applications. -

DMF – ZM – 20 Pulse Valve: Unleashing Superior Performance in Industrial Dust Removal

In the ever – evolving landscape of industrial dust removal technology, the DMF -ZM- 20 pulse valve stands out as a revolutionary electromagnetic pulse valve, redefining the standards of efficiency and reliability. As a cornerstone of pulse – jet dust collection systems, this remarkable valve has become indispensable across a wide spectrum of industries, providing an effective solution to the persistent challenge of dust management.The DMF -ZM- 20, a high – performance right – angle electromagnetic pulse valve, is engineered to deliver precise and powerful pulse – jet cleaning, a critical function for maintaining optimal performance in dust collectors. Its primary role as a compressed air control device is pivotal in ensuring that filter bags are cleaned efficiently, thereby enhancing the overall dust – collecting capacity of the system. With its ability to rapidly open and close, the DMF - ZM – 20 pulse valve releases a short, intense burst of compressed air, dislodging dust from the filter surfaces and preventing clogging. This pulsed cleaning mechanism is not only energy – efficient but also significantly extends the lifespan of the filter bags, reducing maintenance costs and downtime.One of the key features that sets the DMF - ZM – 20 pulse valve apart is its innovative design. The 90 – degree angle between the inlet and outlet ports optimizes air flow dynamics, minimizing pressure loss and maximizing the force of the pulse – jet. This design ensures seamless integration with air bags and blowpipes in dust collector systems, facilitating easy installation and maintenance. The valve’s robust construction, typically crafted from high – grade aluminum alloy, offers excellent resistance to corrosion and wear, making it suitable for harsh industrial environments. The use of premium materials, such as nitrile butadiene rubber (NBR) for the diaphragm, further enhances the valve’s durability and sealing performance, ensuring consistent and reliable operation even under frequent cycling.The working principle of the DMF – ZM- 20 electromagnetic pulse valve is a testament to its engineering excellence. When the valve is in the closed state, compressed air enters the rear chamber through a small orifice, building up pressure that holds the diaphragm against the valve seat. Upon receiving an electrical signal from the pulse – jet control unit, the electromagnetic coil is activated, pulling the armature and opening the exhaust port. This sudden release of pressure in the rear chamber causes the diaphragm to snap open, allowing a powerful blast of compressed air to be discharged through the valve outlet. Once the electrical signal ceases, the armature returns to its original position, closing the exhaust port and allowing the rear chamber to repressurize, resetting the valve for the next pulse – jet cycle. This rapid and precise operation is what makes the DMF - ZM – 20 an ideal choice for high – speed, high – volume dust removal applications.In the cement manufacturing industry, where dust generation is a major concern, the DMF - ZM – 20 pulse valve has proven to be a game – changer. By providing consistent and powerful pulse – jet cleaning, it ensures that baghouse filters remain clean and efficient, reducing emissions and improving air quality in the production area. Similarly, in the steel and metalworking sectors, the valve’s ability to withstand high temperatures and abrasive dust makes it a preferred choice for maintaining the performance of industrial dust collectors. In power plants, the DMF – ZM- 20 pulse valve plays a crucial role in keeping electrostatic precipitators and bag filters clean, ensuring compliance with strict environmental regulations.Moreover, the DMF -ZM – 20 electromagnetic pulse valve is highly adaptable, with customizable options available to meet specific application requirements. Whether it’s adjusting the pulse duration, pressure, or frequency, this valve can be fine – tuned to optimize the dust removal process for different types of dust and operating conditions. This versatility, combined with its reliable performance, has made it a popular choice among engineers and plant managers looking for cost – effective and efficient dust removal solutions.In conclusion, the DMF -ZM- 20 pulse valve represents the pinnacle of electromagnetic pulse valve technology, offering unparalleled performance in industrial dust removal. Its innovative design, robust construction, and precise operation make it a reliable and efficient solution for a wide range of industries. As industries continue to strive for cleaner production environments and higher efficiency, the DMF – ZM- 20 pulse valve is set to play an even more significant role in the future of dust management systems, further solidifying its position as a leader in the field of pulse – jet valve technology. -

Analysis of the Function of Diaphragms in Electromagnetic Pulse Valves

In the complex pneumatic systems of modern industry, although the diaphragms of electromagnetic pulse valves may seem insignificant, they play a crucial role. The quality of their performance directly affects the operational efficiency and stability of the entire system. A thorough exploration of the functions of diaphragms in electromagnetic pulse valves helps us better understand the operating mechanisms of industrial equipment.From the perspective of working principles, the diaphragm of an electromagnetic pulse valve is the core component for achieving precise control. When the electromagnetic coil of the electromagnetic pulse valve is energized, an electromagnetic force is generated, attracting the diaphragm to overcome the spring force and back pressure. The diaphragm deforms instantaneously, opening the valve port, allowing compressed air to rapidly pass through the pulse valve into the blowpipe and jet out at high speed in an extremely short time, performing a powerful cleaning of the filter bags in dust collectors. When the electromagnetic coil is de-energized, the electromagnetic force disappears, and the diaphragm quickly resets under the action of the spring force and back pressure, closing the valve port and cutting off the air flow. In this process, the diaphragm acts like an accurate “commander,” controlling the on-off of the air flow through its own deformation and resetting, achieving precise operation of the pulse injection.In dust collection systems, the role of the diaphragm in electromagnetic pulse valves is particularly critical. Take bag dust collectors as an example. As the dust collection work continues, dust will continuously adhere to the surface of the filter bags, increasing resistance and affecting dust collection efficiency. At this time, the pulse injection system controlled by the diaphragm of the electromagnetic pulse valve comes into play. Through an instantaneous high-pressure injection, it removes the dust on the surface of the filter bags, restoring the air permeability of the filter bags and ensuring the long-term stable operation of the dust collector. The rapid response and reliable sealing performance of the diaphragm ensure that each injection is accurate and efficient, extending the service life of the filter bags and reducing maintenance costs. Statistics show that in dust collection systems using electromagnetic pulse valve diaphragms with good performance, the replacement cycle of filter bags can be extended by 30% – 50%.In addition to the dust collection field, diaphragms of electromagnetic pulse valves are also widely used in other industrial scenarios. In industries with extremely high hygiene requirements, such as food and pharmaceuticals, pneumatic conveying systems often use electromagnetic pulse valves to control the conveying of materials. The good sealing and corrosion resistance of the diaphragm can effectively prevent material leakage and contamination, ensuring product quality and safety. In automated production lines of industries such as automotive manufacturing and mechanical processing, diaphragms of electromagnetic pulse valves are used to control the actions of cylinders, enabling precise grasping, handling, and assembly of components. Their fast switching actions and stable performance improve the degree of automation and production efficiency of the production lines.With its unique function of controlling air flow, the diaphragm of the electromagnetic pulse valve plays an indispensable role in the industrial field. With the continuous development of industrial technology, the performance requirements for diaphragms of electromagnetic pulse valves are also increasing day by day. In the future, they will develop towards a more efficient, reliable, and intelligent direction, continuing to escort industrial production. -

ACCU-PULSE DMF-Z-1-40S Right-angle electromagnetic pulse valve

A right-angle electromagnetic pulse valve (commonly referred to as a right-angle type electromagnetic pulse valve) is a structural variant of electromagnetic pulse valves. Its most notable feature is that the air inlet and outlet are distributed at a right angle (90 degrees), making it widely used in pneumatic control systems requiring high flow rates and efficient blowing, particularly in scenarios such as dust removal equipment (e.g., bag dust collectors) and pneumatic conveying systems.Key Features

-

Right-angle Structure

- The vertical design of the inlet and outlet allows for more direct air flow direction change, reducing air resistance and suitable for working conditions requiring rapid blowing and high flow rates.

- Generates a strong impact force during blowing, effectively removing dust from the surface of filter bags or pushing materials.

-

Electromagnetic Control

- Controls the opening and closing of the valve core through the energization or de-energization of an electromagnetic coil, achieving instantaneous release of pulsed air flow (blowing time typically ranges from tens of milliseconds to several seconds).

- Features fast response and precise control, enabling automated operation through an electronic control system.

-

High Reliability

- Compact structure and good sealing performance make it suitable for continuous industrial operations.

- The valve body is mostly made of metal materials (such as aluminum alloy or stainless steel), offering wear resistance and corrosion resistance.

Application Scenarios

- Dust Removal Systems: In bag dust collectors, right-angle electromagnetic pulse valves periodically blow compressed air to remove dust from filter bags and restore their air permeability.

- Pneumatic Conveying: Used to control pulsed conveying of materials in pipelines, especially suitable for efficient transportation of granular or powdery materials.

- Chemical/Environmental Protection Equipment: Serves as a key actuator in automated equipment requiring rapid air flow start-stop.

Selection Considerations

- Interface Dimensions: Choose appropriate inlet and outlet pipe diameters (e.g., DN15, DN25) according to the system pipeline specifications.

- Operating Pressure: Confirm the applicable compressed air pressure range (e.g., 0.4–0.7MPa).

- Blowing Volume: Select a suitable valve capacity (blowing air volume) based on the required dust removal or conveying capacity.

- Power Supply Type: Common options include DC24V or AC220V, which need to match the control system.

- Environmental Adaptability: Consider working conditions such as temperature, humidity, and dust concentration, and select anti-corrosion and dust-proof valve bodies.

-

-

The ACCU-PULSE DMF-Z-25 pulse valve

The DMF-Z-25 pulse valve is a right-angle electromagnetic pulse valve commonly used in the cleaning and injection systems of pulse-jet bag dust collectors, serving as a “switch” for compressed air. The detailed introduction is as follows:

The ACCU-PULSE DMF-Z-25 pulse valve Working Principle

The DMF-Z-25 pulse valve is a pilot-type solenoid valve. When energized, the electromagnetic force drives the pilot valve to open, rapidly reducing the pressure in the upper cavity of the main valve. A pressure difference is formed between the upper and lower cavities of the main valve, and the medium pressure pushes the closing member of the main valve upward, opening the valve and allowing compressed air to spray out through the valve outlet. When power is cut off, the spring force closes the pilot valve, and the inlet medium pressure quickly enters the upper cavity of the main valve through the pilot hole, forming a pressure difference in the upper cavity to close the main valve and stop the pulse valve from exhausting air.The ACCU-PULSE DMF-Z-25 pulse valve Technical Parameters

- Connection Thread: ZG1″

- Nominal Diameter: 25mm

- Working Pressure: 0.3–0.8 MPa

- Applicable Medium: Clean air

- Working Voltage: AC24V, AC110V, AC220V, DC24V, etc.

- Ambient Temperature: -10–55°C

- Diaphragm Service Life: Over 1 million injections

The ACCU-PULSE DMF-Z-25 pulse valve Product Features

- Right-Angle Structure: The 90° angle between the inlet and outlet is suitable for the installation and connection of air bags and dust collector injection pipes. The smooth air flow can provide the required cleaning air pulses.

- Low-Resistance Design: The low gas resistance in the pipe allows it to be used with low-pressure air sources. Compared with high-pressure valves, it can reduce energy consumption and extend the service life of the diaphragm.

- Reliable Performance: It has good sealing performance and fast response capability, ensuring stable operation during frequent pulse injection and guaranteeing the dust cleaning effect of the dust collector.

The ACCU-PULSE DMF-Z-25 pulse valve Application Fields

It is mainly applied in pulse-jet bag dust collectors in industries such as cement, power, chemical, metallurgy, and steel. By cooperating with pulse injection control instruments, it performs row-by-row (chamber-by-chamber) injection cleaning on filter bags, maintaining the resistance of the dust collector within a set range to ensure the dust collector’s processing capacity and dust collection efficiency. -

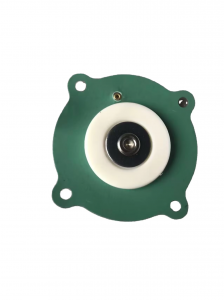

DMF-Z-2-20 ACCU-PULSE valve with nut

DMF-Z-2-20 pulse valve with nut is a right-angle electromagnetic pulse valve commonly used in pulse-jet bag dust collectors as a “switch” for compressed air. The detailed introduction is as follows:

DMF-Z-2-20 ACCU-PULSE Working Principle

The diaphragm divides the electromagnetic pulse valve into front and rear air chambers. When compressed air is connected, it enters the rear air chamber through the orifice, and the pressure in the rear air chamber presses the diaphragm assembly tightly against the valve’s outlet, keeping the electromagnetic pulse valve in the “closed” state. When the pulse injection control instrument sends an electrical signal, the armature of the electromagnetic pulse valve moves backward, opening the rear air chamber and rapidly releasing pressure. The diaphragm assembly moves backward, allowing compressed air to spray out through the valve outlet, and the pulse valve enters the “open” state. When the electrical signal from the pulse injection control instrument disappears, the armature of the electromagnetic pulse valve resets, the exhaust port of the rear air chamber closes, the pressure in the rear air chamber rises, and the diaphragm assembly moves close to the valve’s outlet, re-closing the pulse valve.DMF-Z-2-20 ACCU-PULSE Technical Parameters

- Connection Thread: G3/4″

- Working Pressure: 0.2–0.7 MPa

- Applicable Medium: Clean air

- Working Voltage: DC12V, DC24V, AC110V, AC220V, etc.

- Diaphragm Service Life: Over 1 million injections

Product Features

- Large Air Chamber Volume: The diaphragm lifts to a large height, delivering a high injection volume and providing sufficient dust-cleaning power for the dust collector.

- Flexible Installation: It allows for a larger installation distance, making it easy to operate with tools during installation and offering suitable installation methods. Meanwhile, the larger spacing between filter bags prevents bottom collisions and friction of long bags.

- Superior Diaphragm Performance: The diaphragm is thin, tough, and highly elastic, enabling a large injection distance for each pulse. Even 8-meter-long dust bags can be injected to the bottom.

DMF-Z-2-20 ACCU-PULSE Application Field

It is mainly used in the dust-cleaning injection system of bag-type dust collectors. By cooperating with a pulse injection control instrument, it performs row-by-row (chamber-by-chamber) injection cleaning on filter bags, maintaining the dust collector’s resistance within a set range to ensure dust removal capacity and efficiency. -

ACCU-PULSE DMF-Z-20 pulse valve

DMF-Z-20 pulse valve is a right-angle electromagnetic pulse valve commonly used in pulse-jet bag dust collectors as a “switch” for compressed air. The detailed introduction is as follows:Working Principle

The diaphragm divides the electromagnetic pulse valve into front and rear air chambers. When compressed air is connected, it enters the rear air chamber through the orifice, and the pressure in the rear air chamber presses the diaphragm assembly tightly against the valve’s outlet, keeping the electromagnetic pulse valve in the “closed” state. When the pulse injection control instrument sends an electrical signal, the armature of the electromagnetic pulse valve moves backward, opening the rear air chamber and rapidly releasing pressure. The diaphragm assembly moves backward, allowing compressed air to spray out through the valve outlet, and the pulse valve enters the “open” state. When the electrical signal from the pulse injection control instrument disappears, the armature of the electromagnetic pulse valve resets, the exhaust port of the rear air chamber closes, the pressure in the rear air chamber rises, and the diaphragm assembly moves close to the valve’s outlet, re-closing the pulse valve.Technical Parameters

It is mainly used in the dust-cleaning injection system of bag-type dust collectors. By cooperating with a pulse injection control instrument, it performs row-by-row (chamber-by-chamber) injection cleaning on filter bags, maintaining the dust collector’s resistance within a set range to ensure dust removal capacity and efficiency. -

Electromagnetic Pulse Valves: Opening a New Era of Intelligent Industrial Cleaning

With the advent of the intelligent industrial era, electromagnetic pulse valves are also actively integrating into the intelligent wave and becoming a key part of realizing intelligent industrial cleaning.Intelligent electromagnetic pulse valves are equipped with advanced sensors and intelligent control systems. These sensors can real – time monitor key parameters such as the resistance of the filter bag, dust concentration, and the operating status of the equipment. Take the large – scale dust removal system in a chemical enterprise as an example. The sensors transmit the collected data to the intelligent control system in real – time. The system analyzes and processes these data to accurately judge the ash – cleaning requirements of the filter bag. When the resistance of the filter bag reaches the set threshold, the intelligent control system automatically issues an instruction to control the electromagnetic pulse valve for ash – cleaning operation. Moreover, the system can automatically adjust the injection time, injection interval, and injection pressure of the electromagnetic pulse valve according to the actual situation to ensure the ash – cleaning effect while minimizing energy consumption.The intelligence of electromagnetic pulse valves is also reflected in remote monitoring and fault diagnosis functions. With the help of the Internet of Things technology, enterprise managers can remotely monitor the operating status of electromagnetic pulse valves at any time through terminal devices such as mobile phones and computers. Once a fault occurs in the equipment, the intelligent system can quickly issue an alarm and accurately locate the fault point through data analysis. For example, in the dust removal equipment of the mining industry, if a fault such as valve core jamming occurs in the electromagnetic pulse valve, the intelligent system will immediately notify the maintenance personnel and provide detailed fault information, greatly shortening the equipment maintenance time and improving production efficiency.The intelligent transformation of electromagnetic pulse valves has brought higher efficiency, lower costs, and more reliable operation guarantees for industrial cleaning. It has opened a new era of intelligent industrial cleaning, enabling industrial production to continuously move forward on the path of environmental protection and high – efficiency, laying a solid foundation for realizing a sustainable industrial future. -

Electromagnetic Pulse Valves: Key Equipment for Promoting the Upgrading of the Environmental Protection Industry

The environmental protection industry occupies an increasingly important position in today’s social development. As a key component of environmental protection equipment, electromagnetic pulse valves are promoting the technological upgrading and efficient development of the environmental protection industry.Picture (DMF-Z-40S Pulse Valve)

Electromagnetic pulse valves have the significant advantage of fast response speed. In some production environments with extremely strict requirements for dust emissions, such as electronic chip manufacturing workshops, electromagnetic pulse valves can respond in a very short time. Once it is detected that the dust accumulation on the surface of the filter bag reaches a certain level, the control system issues an instruction, and the electromagnetic pulse valve can quickly open and complete a pulse injection action within a few milliseconds, timely removing the dust on the filter bag and ensuring that the air quality in the workshop always meets strict standards, providing a clean environment for precision production.

The energy – saving characteristics of electromagnetic pulse valves are also remarkable. The ash – cleaning methods of traditional dust removal equipment often consume a large amount of energy. Modern electromagnetic pulse valves, through optimized design, can precisely control the injection volume and injection time of compressed air. For example, in the small – scale dust removal system used in a food processing factory, the electromagnetic pulse valve adopts intelligent control technology. It automatically adjusts the injection parameters according to the actual working conditions of the filter bag. In this way, while meeting the ash – cleaning requirements, it greatly reduces the waste of compressed air, reducing the energy consumption and operating costs of enterprises.On the path of the environmental protection industry’s continuous pursuit of green and efficient development, the importance of electromagnetic pulse valves has become more prominent. It not only improves the performance and reliability of environmental protection equipment but also provides strong support for enterprises to achieve energy conservation, emission reduction, and sustainable development. With the increasingly strict environmental protection standards, electromagnetic pulse valves will have a broader development space and continue to contribute to the upgrading of the environmental protection industry. -

Electromagnetic Pulse Valves: The Core Power of Industrial Dust Removal Systems

In modern industrial production, dust pollution not only poses a threat to the environment but also seriously endangers the normal operation of production equipment and the health of workers. As a key component of industrial dust removal systems, electromagnetic pulse valves play an irreplaceable role.The working principle of electromagnetic pulse valves is based on the law of electromagnetic induction. When the electromagnetic coil of an electromagnetic pulse valve is energized, the generated electromagnetic force overcomes the spring force, lifts the valve core, opens the gas passage, and allows compressed air to spray out rapidly. When the electromagnetic coil is de-energized, the electromagnetic force disappears, and the spring force makes the valve core return to its original position, closing the gas passage and stopping the gas injection. This rapid opening and closing action can precisely control the injection time and frequency of compressed air.In the field of industrial dust removal, electromagnetic pulse valves are widely used. Take a cement plant as an example. A large amount of dust is generated during the production process. In a bag filter, the electromagnetic pulse valve emits a pulse jet at regular intervals. The compressed air is sprayed into the interior of the filter bag at high speed. The strong air flow impact causes the filter bag to expand and vibrate instantaneously, shaking off the dust attached to the surface of the filter bag, thus achieving the ash cleaning of the filter bag. In this way, not only can the air permeability of the filter bag be ensured, the high – efficiency operation of the dust collector be maintained, but also the service life of the filter bag can be extended, reducing the operating costs of enterprises.In other industrial fields such as steel plants and thermal power plants, electromagnetic pulse valves also play an important role. They ensure a clean production environment, reduce the erosion of dust on equipment, and improve the safety and stability of production. With the continuous progress of industrial technology, electromagnetic pulse valves are also constantly innovating and developing, moving towards higher performance, more energy – saving, and more intelligent directions to meet the needs of future industrial development. -

Smart Sensors Empower Electromagnetic Pulse Valves, Driving Digital Upgrades in Dust Removal Systems

Advancing industrial intelligence is transforming traditional dust removal equipment through technological innovation. Take the ASCO 353 series pulse valve as an example – its integration with digital sensors provides real-time monitoring and intelligent control solutions for dust systems.Intelligent Monitoring Architecture

This system combines dust concentration meters, differential pressure transmitters, and air tank pressure sensors to collect critical data like filter bag resistance, jetting pressure, and air flow. For instance, differential pressure sensors trigger automatic jetting when resistance thresholds are exceeded, while air tank sensors ensure stable jetting pressure to prevent cleaning failures.Digital Management Advantages- Predictive Maintenance: Analyzing diaphragm cycle frequency and response times predicts component wear and blockages, minimizing downtime.

- Energy Optimization: Dynamic parameter adjustments based on real-time pressure reduce compressed air waste while maintaining cleaning effectiveness.

- Remote Control: Cloud-based platforms enable remote status monitoring and cycle adjustments for cross-regional management.

Case Study

A steel plant deploying smart pulse valves in its sintering machine dust system achieved:- 30% reduction in collector resistance fluctuations

- 25% decrease in jetting frequency

- Annual energy cost savings of ¥180,000

Stable dust emissions below 10mg/m³ were also maintained, supported by automated operational reports for process optimization.

Looking ahead, IoT integration will drive pulse valves toward “adaptive cleaning” through AI algorithms dynamically matching changing operating conditions, propelling industrial dust removal toward higher efficiency, lower carbon footprint, and unmanned operation. -

Performance Comparison and Selection Guide for Submerged vs. Right-Angle Pulse Valves

Submerged and right-angle electromagnetic pulse valves represent two primary designs in pulse bag dust collectors, with structural differences directly affecting cleaning efficiency and energy consumption.Structural & Operational Characteristics

Submerged valves feature a fully integrated design flush with the air tank interior. Their dual-section diaphragm uses pressure differentials to control opening/closing, enabling direct airflow to filter bags with faster response and stronger jetting. Right-angle valves use perpendicular inlet/outlet configurations with standalone mounting, offering simplicity and ease of maintenance but slightly higher resistance due to 90° airflow turns.Performance Benchmarks- Jetting Efficiency: Submerged valves deliver 20% higher airflow than equivalent right-angle models, maintaining stability even at low pressures (0.3MPa).

- Energy Savings: Their rapid actuation reduces jetting time, achieving 15%+ compressed air savings through optimized diaphragm design.

- Installation Flexibility: Right-angle valves support threaded/flanged connections for versatile layouts, while submerged valves require custom air tank interfaces ideal for new installations or large-scale retrofits.

Selection Recommendations- Unstable Pressure Environments: Prioritize submerged valves with their 0.3-0.8MPa pressure tolerance.

- Space Constraints: Right-angle valves’ compact design suits small systems or renovation projects.

- Long-Term 经济性: Submerged valves’ energy efficiency and extended diaphragm life (2+ million cycles) make them ideal for continuous industrial operations.